Ryan_G

Yamaha

- Location

- Fresno, CA

I decided to build up a RN hull for the surf. My SN is starting to crack up a bit.

I Got this 2001 round nose hull to start with. She is a little rough, but I see potential.

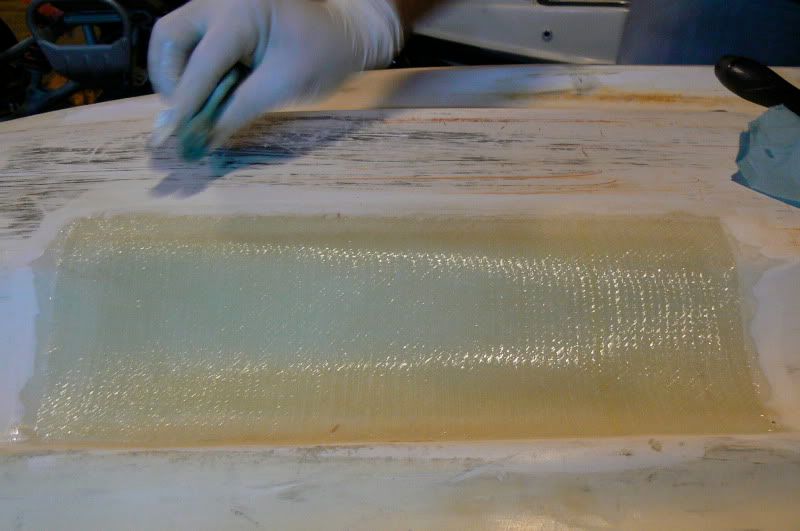

This will be my first attempt to do any fiberglass work. I was also thinking of painting it myself.

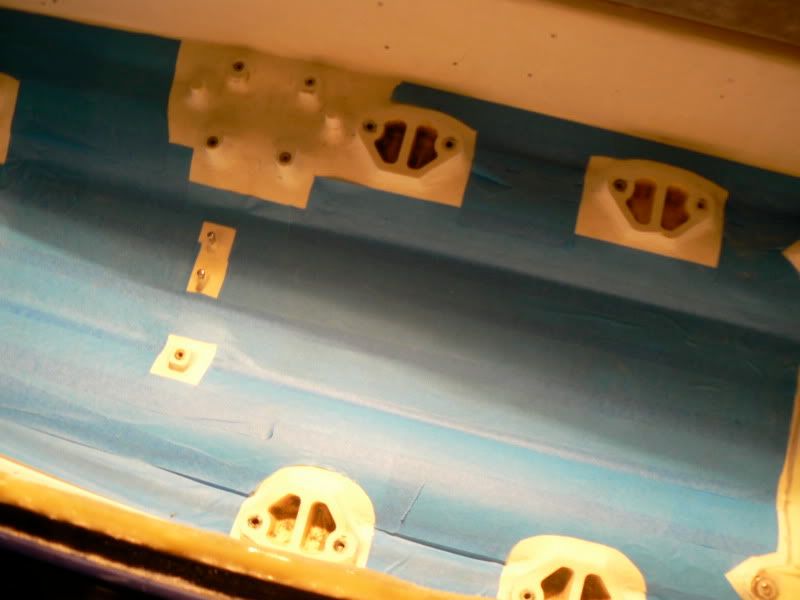

Here Are some pictures after I cleaned it up. I scrubbed the inside with ajax and steel wool. I also used a 3M eraser wheel to clean off some of the ugly green turf remnants.

I Got this 2001 round nose hull to start with. She is a little rough, but I see potential.

This will be my first attempt to do any fiberglass work. I was also thinking of painting it myself.

Here Are some pictures after I cleaned it up. I scrubbed the inside with ajax and steel wool. I also used a 3M eraser wheel to clean off some of the ugly green turf remnants.

Last edited: