oxnard111

Creative RE Purchasing

- Location

- so Cali, Ventura/Oxnard area

Geoff's black WDK hood arrived like yours. He wet sanded and buffed it out and it looked soooo good. So glossy and pretty.

lol trust me i know, anywhere it could have leaked, leaked!See that brown spot by the cooling line?

It leaked there.

Seal everything REALLY well. Those pump inserts included.

u know this!!Dayum,,,, whats the plan for the foam?

stfu!:banghead:big south swell on the way..better get to work!!

big south swell on the way..better get to work!!

Talk to Cuong, see how he is liking my front foothold setup.i got asked how i bolted down my straps to my tray..

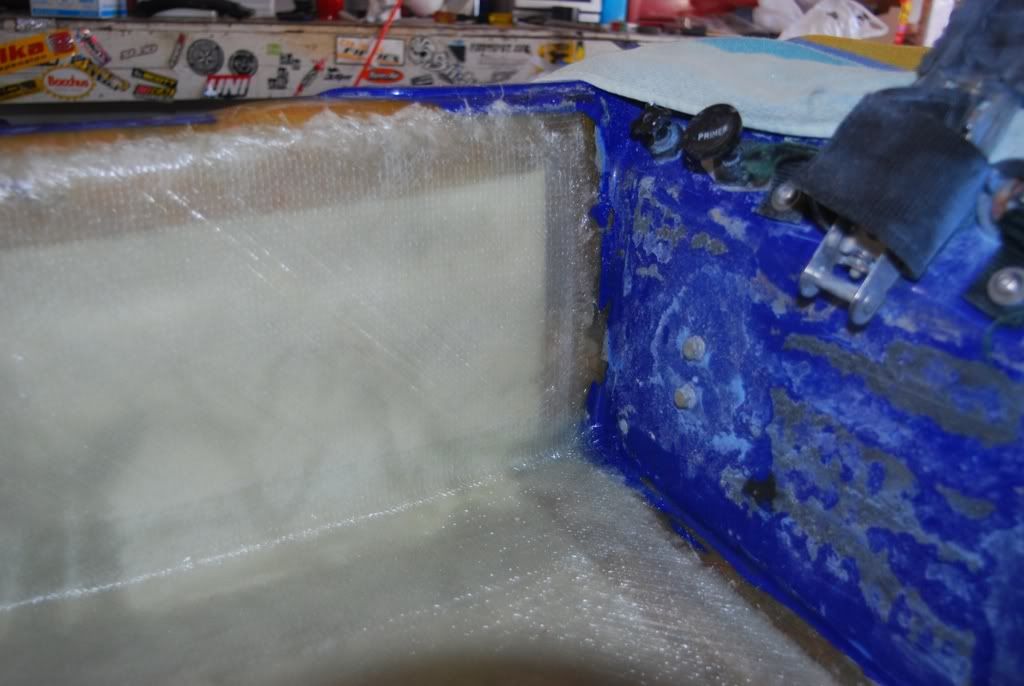

first i took some 2.5x2.5x.125 inch stainless steel plates and roughed them up deeply with a hacksaw. did the same to the tray, only with heavy grit sandpaper(sandCLOTH is 1000x better, its more expensive but lasts a long, LONG time. worth it for sure.) laid out epoxy over the tray and set the plates where i needed them and filled around the edges with more epoxy. i let it cure and then drilled the holes for where i wanted the bolts to go at the correct size for my tap. i then tapped the holes and bolted down the straps.

now what i SHOULD have done is different.

this is what i would do if i was to do it again. use the same size plates but instead of just chip up the tray first cut a hole for where the bolts will go and dig out some foam if needed and fill it up with 5200 and lay the plate down making a seal. then glass over the edges or whole plate and reinforce the tray at the same time. drill the holes and tap for bolts. braap!

Talk to Cuong, see how he is liking my front foothold setup.

that thing is gonna be so solid

what kinda turf?