There is lots of good advice in this thread.

I think you should find out what the issue is, or more likely issues are, “before throwing the baby out with the bathwater” and switching to a 760 setup. Many guys are running a 62t setup sucessfully. It is easy to swap an oem 62t flywheel to see if that is the issue. Leave it in there while you test for other things.

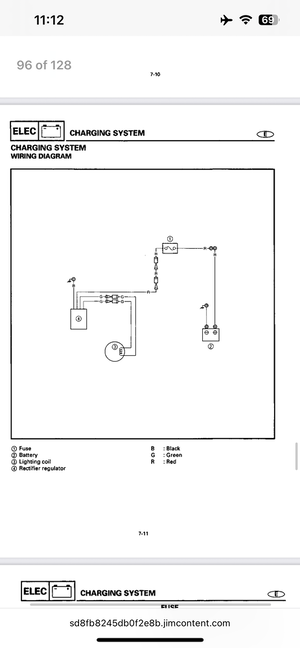

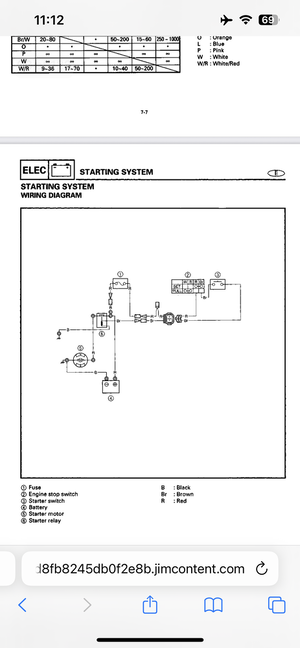

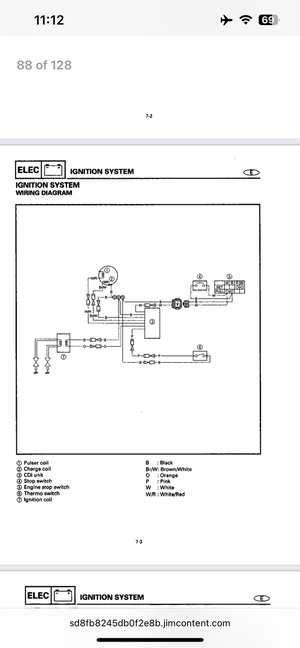

As others have said above, secure and stable power and ground cables and connections are needed for any electrical system to function and be reliable. Your pics show many wiring issues which are common, we see them all the time in skis.

All cables need to be marine grade, which means no raw copper wire. Copper is highly conductive, but also highly corrosive. Marine grade wire is tinned to slow down this corrosion.

The crimps in most or all of these pics are upside down. They look weak and possibly intermitently tight if at all.

Most crimp on terminals are made from flat metal which is rolled, and the joint is on top. There are different types of crimpers for insulated and for uninsulated terminals, either can make a good crimp.

When you crimp a terminal, make sure the rounded part of your crimp tool matches up with the line where the 2 ends of the metal meet. Then when you crimp they stay tight together and the tool’s crimp pin pushes in from the bottom against solid metal. You get a nice tight crimp this way.

More upside down weak crimps on wires. Extra wire splices, non waterproof butt splices and terminals all over the place. Your system is as reliable as the weakest connection.

New power, starter, and ground cables, new ebox gasket, new fuse holder assembly should be installed before you do anymore testing.

I think you should find out what the issue is, or more likely issues are, “before throwing the baby out with the bathwater” and switching to a 760 setup. Many guys are running a 62t setup sucessfully. It is easy to swap an oem 62t flywheel to see if that is the issue. Leave it in there while you test for other things.

As others have said above, secure and stable power and ground cables and connections are needed for any electrical system to function and be reliable. Your pics show many wiring issues which are common, we see them all the time in skis.

All cables need to be marine grade, which means no raw copper wire. Copper is highly conductive, but also highly corrosive. Marine grade wire is tinned to slow down this corrosion.

The crimps in most or all of these pics are upside down. They look weak and possibly intermitently tight if at all.

Most crimp on terminals are made from flat metal which is rolled, and the joint is on top. There are different types of crimpers for insulated and for uninsulated terminals, either can make a good crimp.

When you crimp a terminal, make sure the rounded part of your crimp tool matches up with the line where the 2 ends of the metal meet. Then when you crimp they stay tight together and the tool’s crimp pin pushes in from the bottom against solid metal. You get a nice tight crimp this way.

More upside down weak crimps on wires. Extra wire splices, non waterproof butt splices and terminals all over the place. Your system is as reliable as the weakest connection.

New power, starter, and ground cables, new ebox gasket, new fuse holder assembly should be installed before you do anymore testing.