You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Confused on best reinforcing

- Thread starter MDStandUp

- Start date

- Location

- Annapolis, Maryland

those are some nice nose jobs. but i got a lot more damage that those wouldn't hide. i dont know that im ready to say that i need a new nose put on though. i think im kind in the middle with this one. can you make a mold on top of you original (not damaged) nose that i could lay right ontop of all the damage with some 5200 and then maybe wrap a couple 4'' pieces of glass around the cover molded part to the bottom of the lip? also a bottom piece to sandwich all the damage in the middle. basically what you got there but continue it up to the yamaha emblem and have a bottom one too. id pay good money for something like that.

Last edited:

kraqus

Site Supporter

- Location

- Great State of Texas

Yes you can do that BUT skip the 5200. Use Epoxy all the way with some filler, either Cab-O-sil or 404. That is structural damage you have. You need to reinforce that area really well.

Benny

Benny

Last edited:

LBE

Eddie Would Go.

- Location

- Charlotte, NC

. id pay good money for something like that.

Call Blowsion. They have several different nose molds for repairing. It is not an advertised thing, but I asked Johnny about this a year or so ago and he sent me several pics of various nose pieces. I picked what I needed and ordered. They have the top and bottom nose pieces for a "sandwhich" type repair.

Price all depends on what you need/want. They can make the pieces in thick carbon to lightweight glass pieces. They can make you a nose piece that goes all the way to the hood!

Phone # is in my sig.

Tell them Eddie sent you. HA!

- Location

- Annapolis, Maryland

Call Blowsion. They have several different nose molds for repairing. It is not an advertised thing, but I asked Johnny about this a year or so ago and he sent me several pics of various nose pieces. I picked what I needed and ordered. They have the top and bottom nose pieces for a "sandwhich" type repair.

Price all depends on what you need/want. They can make the pieces in thick carbon to lightweight glass pieces. They can make you a nose piece that goes all the way to the hood!

Phone # is in my sig.

Tell them Eddie sent you. HA!

Thanks guys i guess my million dollar idea is already out there. Apparently your and PM have already made it. so much on the money idea, hell yeah on the fix.

kraqus

Site Supporter

- Location

- Great State of Texas

Woody

Need to save my money!!

- Location

- Long Island

do you make something like that for a SN? a riding buddy lovessss his SN but busted in the front of it

- Location

- Annapolis, Maryland

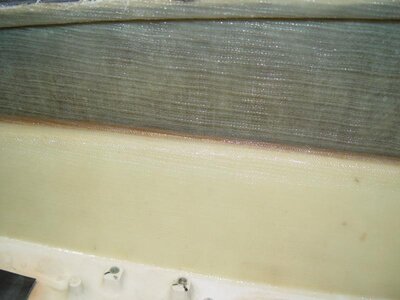

You like this? Like I said many ways to fix the same problem...

yeah i think that is it. that looks to be a top piece right. im guessing that would sit flosh over the damaged area.

- Location

- Annapolis, Maryland

Is this a good line up to completely reinforce 2 B1s and SJ with mashed in nose.

FG-7725-38 8.5oz twill e cloth 38"X25yds 38" Width $156.25

FG-C04Y 8.7oz eglass tape 4" Width 20 yards $20.00

EPOX-635314 1 gal resin 43oz hard MED $65.00

EPX-P31 pump system for epoxy set of 2 $6.25

AC-BL004 black dye 4oz. $5.60

FL-3M050 3M micro bubbles will do 5QTs $9.75

$262.85 total minus rollers/plastic scrapes and the basics.

What do you guys think. Right/Wrong glass or epoxy combo's

FG-7725-38 8.5oz twill e cloth 38"X25yds 38" Width $156.25

FG-C04Y 8.7oz eglass tape 4" Width 20 yards $20.00

EPOX-635314 1 gal resin 43oz hard MED $65.00

EPX-P31 pump system for epoxy set of 2 $6.25

AC-BL004 black dye 4oz. $5.60

FL-3M050 3M micro bubbles will do 5QTs $9.75

$262.85 total minus rollers/plastic scrapes and the basics.

What do you guys think. Right/Wrong glass or epoxy combo's

WaveDemon

Not Dead - Notable Member

- Location

- Hell, Florida

I don't see any mat in your materials list which is fine. I don't like mat unless it's for a very complex shape (making footholds) or when I"m being lazy and dont want to cut cloth and would rather just tear off chunks of mat. Mat holds a lot of resin (and requited a lot of resin to wet out) and ends up being heavier when all is said and done.

you don't need the tape either. If you want tape just cut your cloth into strips.

The 8.5 twill is real nice. I've used it and it lays down better than most other cloths, it conforms about as nice as mat without the extra weight (with resin). Be aware you are paying extra for this weave compared to a similar weight reagular cloth.

I'm assuming the micro bubles are for filling the bond line. You can do that, lots of people do. I personally like filling the bond line with 2 part foam because it's easier to sand.

everything else looks good. good luck, have fun.

One more thing to ad to your "basics". buy talc from us composites too and cover your skin with it before you do any sanding to help reduce itching.

you don't need the tape either. If you want tape just cut your cloth into strips.

The 8.5 twill is real nice. I've used it and it lays down better than most other cloths, it conforms about as nice as mat without the extra weight (with resin). Be aware you are paying extra for this weave compared to a similar weight reagular cloth.

I'm assuming the micro bubles are for filling the bond line. You can do that, lots of people do. I personally like filling the bond line with 2 part foam because it's easier to sand.

everything else looks good. good luck, have fun.

One more thing to ad to your "basics". buy talc from us composites too and cover your skin with it before you do any sanding to help reduce itching.

- Location

- Annapolis, Maryland

Thanks for all your suggestions. I'd spend 3 times this without everyones help.

What is the difference in the foam on UScomposites.com and spray foam that you would buy in a can at home depot used to seat door and window surrounds?

Does it have to do with water not being able to penetrate the USC foam or is it just so expensive cause its got the Coastgaurd approval stamp on it?

What is the difference in the foam on UScomposites.com and spray foam that you would buy in a can at home depot used to seat door and window surrounds?

Does it have to do with water not being able to penetrate the USC foam or is it just so expensive cause its got the Coastgaurd approval stamp on it?

WaveDemon

Not Dead - Notable Member

- Location

- Hell, Florida

it's different stuff. the 2 part foam cures hotter. it's harder when cured and has a bit of a shell to it.

- Location

- Annapolis, Maryland

would you not recommend insullation foam even on a budget build?

it's different stuff. the 2 part foam cures hotter. it's harder when cured and has a bit of a shell to it.

kraqus

Site Supporter

- Location

- Great State of Texas

Is this a good line up to completely reinforce 2 B1s and SJ with mashed in nose.

FG-7725-38 8.5oz twill e cloth 38"X25yds 38" Width $156.25

FG-C04Y 8.7oz eglass tape 4" Width 20 yards $20.00

EPOX-635314 1 gal resin 43oz hard MED $65.00

EPX-P31 pump system for epoxy set of 2 $6.25

AC-BL004 black dye 4oz. $5.60

FL-3M050 3M micro bubbles will do 5QTs $9.75

$262.85 total minus rollers/plastic scrapes and the basics.

What do you guys think. Right/Wrong glass or epoxy combo's

You are using 3:1 ratio Epoxy which is great as it will buy you time for a first time.

Tape is up to you, I did not use it on mine but I still double up the glass layers.

3M glass bubbles are OK, I guess, but remember you are not going to sand it.

Apply the "peanut butter" and when sticky lay the glass, all at once.

When it cures, it will cure ALL together, bondline and glass as one piece.

I used West Systems 404 instead. You can use Cab-O-sil too.

Other than that looks good.....now go and Hack it!

Benny

WaveDemon

Not Dead - Notable Member

- Location

- Hell, Florida

You are using 3:1 ratio Epoxy which is great as it will buy you time for a first time.

Tape is up to you, I did not use it on mine but I still double up the glass layers.

3M glass bubbles are OK, I guess, but remember you are not going to sand it.

Apply the "peanut butter" and when sticky lay the glass, all at once.

When it cures, it will cure ALL together, bondline and glass as one piece.

I used West Systems 404 instead. You can use Cab-O-sil too.

Other than that looks good.....now go and Hack it!

Benny

I've always tried to not use extra epoxy resin because it's not cheap and it's not light. I don't understand why people use it to fill bond lines. The point of filling bond lines is to make a smooth transition from the top deck to the bottom deck for reinforcing the whole side. the bond line it's self doesn't need to be any stronger.

Last edited:

kraqus

Site Supporter

- Location

- Great State of Texas

I used less than 12 OZ of mix epoxy on each bond line side, just enough to fill that gap but still at an angle.

That is a bit over one pound if you add it up, not a significant increase in weight...IMO.

I guess Foam will work just fine.....

Surfboards are really strong if you consider the fact that they are nothing but a sandwich of foam between fiberglass layers.

Ease of use? No sanding? I dunno....but will definitely add strength to it.

BTW..I have seen cracks right above and below the bond line.

Let's not confuse this Lad anymore....:haha:

Benny

That is a bit over one pound if you add it up, not a significant increase in weight...IMO.

I guess Foam will work just fine.....

Surfboards are really strong if you consider the fact that they are nothing but a sandwich of foam between fiberglass layers.

Ease of use? No sanding? I dunno....but will definitely add strength to it.

BTW..I have seen cracks right above and below the bond line.

Let's not confuse this Lad anymore....:haha:

Benny

Last edited:

- Location

- Annapolis, Maryland

The bond line will be stronger if you use the less=more approach. Notice how the material conforms to the shape of the hull (bond line)...

is that foam or resin bubbles you used to do that.

What is the purpose of even filling that? Why not stretch the cloth across the bond line and let it set. Im guessing water getting behind there but wouldnt be good but i would just figure to build up either side of the cloth.

WaveDemon

Not Dead - Notable Member

- Location

- Hell, Florida

would you not recommend insullation foam even on a budget build?

you could probably get away with that. don't try it when refoaming the tray though.