- Location

- Kitchener, ontario

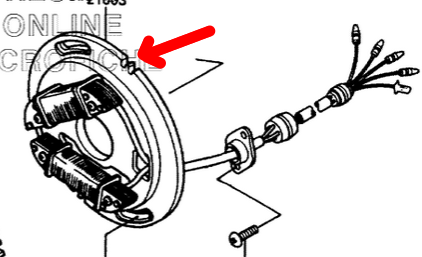

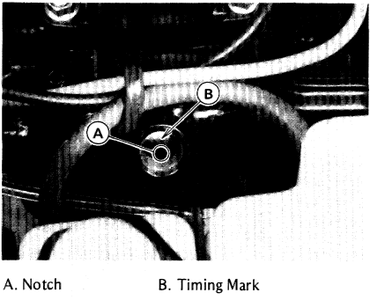

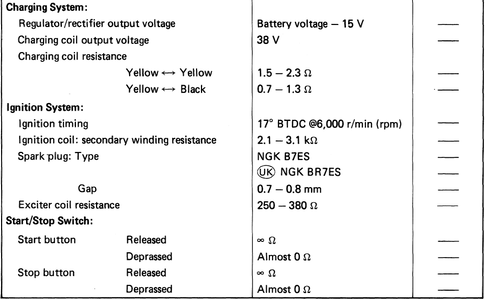

Machine died..had no spark, replaced the stator and igniter..have spark, compression and fuel but it won't even bark...I am completely at a loss as to why it won't fire..any thoughts what could be wrong with this thing? Was thinking timing...tried multiple positions on the stator but not even a fart...thanks