SUPERJET-113

GASKETS FOR CHAMP BRAP!

- Location

- Lake Havasu City, AZ USA

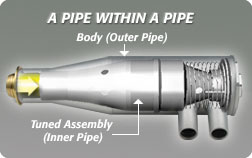

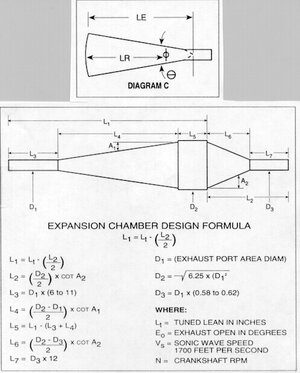

I dont know if this has been mentioned before, but it would be awesome to have something like this on our ski's! Would it be possible to make one for a PWC? Maybe some of you R/C head will know more about this contraption.

It aint to gawd damn buku! :Banane26: :doh::laugh2:

http://www.bukupower.com/

YouTube - BUKU POWER ACTIVE PIPE

It aint to gawd damn buku! :Banane26: :doh::laugh2:

http://www.bukupower.com/

YouTube - BUKU POWER ACTIVE PIPE