- Location

- Tualatin, OR

Before I begin, a little history. I have spent 20+ years owning and riding standup jet ski's but never tried to put one together from scratch. Most of my experience has been on Kawis. I spent a year on a -7 Superfreak Badass, but that was built for me by Zack with PHP.

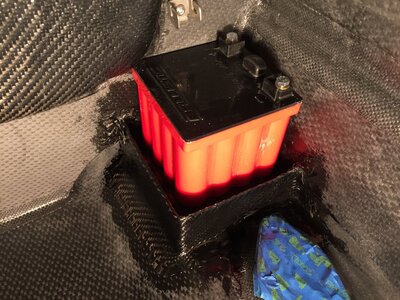

That was a fun hull but once the freestyle bug got its teeth into me, I knew I needed to do some upgrades over the winter. Starting with a PHP 900 and after a lot of time on the X, the plan came together. A DVX hull, upgrade to a 155 pump, full race domes, and total loss.

I am about 1/2 way through the build but figured better late than never on starting a build thread. There are some things that I had to figure out along the way that I will try to point out so it might save the next novice some time. Also, no one on here is very shy and if I am doing something stupid, I am confident that someone will point it out.

I guess I will start at the beginning when the ski showed up. The ski was so clean. Almost no prep work required.

From the Front

Love the X in the engine bay that only shows up in pictures.

Interesting part was the carbon/Kevlar on the tray. It was thinner and more flexible than I would have expected.I suspect that is for weight savings. I trust Xscream knows what they are doing and that it will be strong enough. If not, I will find out soon enough. Its just turf, carbon, and epoxy to fix it.

Since someone is going to ask, Weight as it showed up for the hull, hood, pole, shoe, steering, bars, and ride plate was 73lbs. According to my bathroom scale.

That was a fun hull but once the freestyle bug got its teeth into me, I knew I needed to do some upgrades over the winter. Starting with a PHP 900 and after a lot of time on the X, the plan came together. A DVX hull, upgrade to a 155 pump, full race domes, and total loss.

I am about 1/2 way through the build but figured better late than never on starting a build thread. There are some things that I had to figure out along the way that I will try to point out so it might save the next novice some time. Also, no one on here is very shy and if I am doing something stupid, I am confident that someone will point it out.

I guess I will start at the beginning when the ski showed up. The ski was so clean. Almost no prep work required.

From the Front

Love the X in the engine bay that only shows up in pictures.

Interesting part was the carbon/Kevlar on the tray. It was thinner and more flexible than I would have expected.I suspect that is for weight savings. I trust Xscream knows what they are doing and that it will be strong enough. If not, I will find out soon enough. Its just turf, carbon, and epoxy to fix it.

Since someone is going to ask, Weight as it showed up for the hull, hood, pole, shoe, steering, bars, and ride plate was 73lbs. According to my bathroom scale.