- Location

- Buffalo, NY

Hey guys, I need some help and some suggestions if you could help me out. Long story short, at some point in its life, someone used regular screws, not stainless ones in the hood hinge and they were severely corroded and flaking apart, so much so that there waere rust stains on the gelcoat of the hull. I got 2 of the very rusty screws out successfully with an easy out, but 3 of them wouldn't budge and they were so rusted the brass hull inserts spun when I tried using the easy-out on them with the screws still stuck in them.

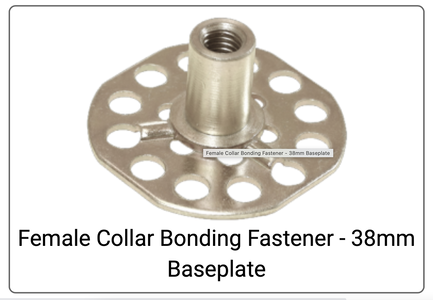

The 3 holes in a row on the top in the photos are the damaged ones. How would you guys recommend removing the old damaged brass hull inserts and putting new ones in so that it's nice and strong? I figured on cutting out the fiberglass around the hull inserts, getting some new ones, mixing up some Cabosil, chopped strand, and epoxy and then pouring it in around the hull inserts and then putting a couple sheets of 1708 over them, but I wanted to see if you guys had any better ideas before I do that. Thanks in advance.

The 3 holes in a row on the top in the photos are the damaged ones. How would you guys recommend removing the old damaged brass hull inserts and putting new ones in so that it's nice and strong? I figured on cutting out the fiberglass around the hull inserts, getting some new ones, mixing up some Cabosil, chopped strand, and epoxy and then pouring it in around the hull inserts and then putting a couple sheets of 1708 over them, but I wanted to see if you guys had any better ideas before I do that. Thanks in advance.