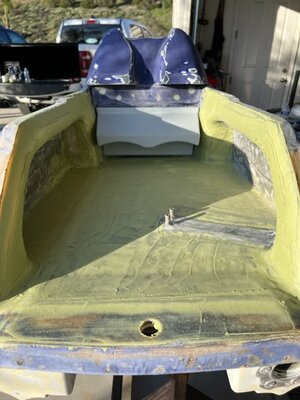

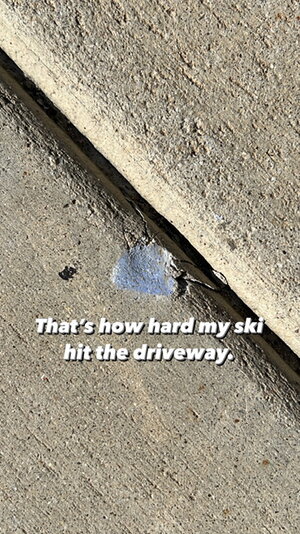

Started to block out the primer last weekend and then I hit a bit of a rut. I ordered a lowered nose piece and it didn’t work out. So I started working on my nose piece that I shaped out of foam and was chasing pinholes. Got it all sanded down and when I went to clean it with acetone, it went into the pinholes down to the foam and started eating the foam. Total waste of a day. I’m a teacher and this week is spring break, you’d think that progress would be fast but I’m struggling for motivation. I have so many different aspects of this project going on that it doesn’t seem like I’m making any progress. So I’m loading up the square and going to havasu in the morning. Maybe some laps will get me amped to finish the round.

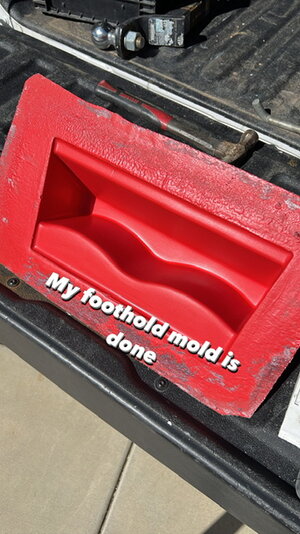

Enough of that, today I decided to work on my sponsons. The sponsons that came with the ski were in great condition, but after doing my foothold, nose piece, the bilge reinforcement, and eventually the rear bumpers in visual carbon, I decided I want my sponsons to be made out of carbon as well. So today I got some pieces of sheet metal, tacked them up to make a corner piece and then through bolted the sponson to the sheet. This will give me a nice flange edge to eventually bag my carbon sponsons. Waxed the plug and flange a bunch, sprayed a bunch of PVA, and then used up the remainder of my tooling gel.

I’m spraying this with the purple harbor freight gun with a 2.5 tip.

That’s all the progress until next week, I’m going to the river. If you see my square with 19 graphics at body beach, come shoot the stuff.