dirkdiggler

Vendor Account

- Location

- WI

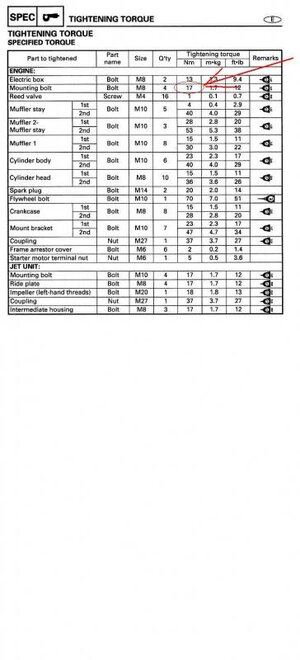

how many ft. lbs of torque for the 8 bolts that hold the mount to the hull??? Cant find anywhere for what yamaha recommends for an FX-1 or superjet????

When you place the motor on the engine mounts and only hand tighten the 4 motor mount bolts there is alot of play if you grab the motor and move it around every which way. The bed plate hole is pretty large and alows some movment that seems like it could throw the alingment off!

12 ft. lbs of torque on the motor mount bolts does not seem like enough to prevent the motor from moving around from vibration on its own?? Does what im asking make sense?

When you place the motor on the engine mounts and only hand tighten the 4 motor mount bolts there is alot of play if you grab the motor and move it around every which way. The bed plate hole is pretty large and alows some movment that seems like it could throw the alingment off!

12 ft. lbs of torque on the motor mount bolts does not seem like enough to prevent the motor from moving around from vibration on its own?? Does what im asking make sense?