- Location

- Delray Beach, FL

Hey guys I decided that i want to put foot holds on my 00' SJ. Did a bit of research but got mixed reviews on which ones to get. I was leaning towards watercraft factory. This will be my first time doing this install, i have no experience in cutting or fiberglass work. All I have done myself was, 0 bars, billet throttle, bilge pump, hydro turf, and removed/installed carbs on my own.

I was hoping someone can point me to do a good how to write up on the install process. Also, all the materials ill need and if there's a place I can buy all the materials in one shot.

Thanks!

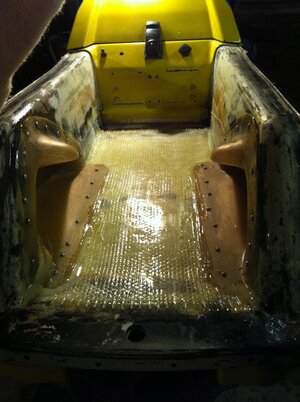

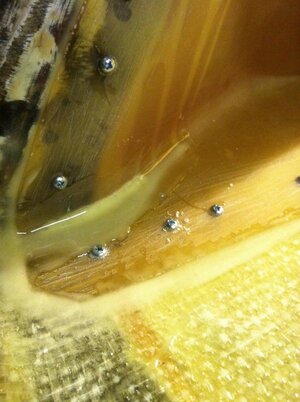

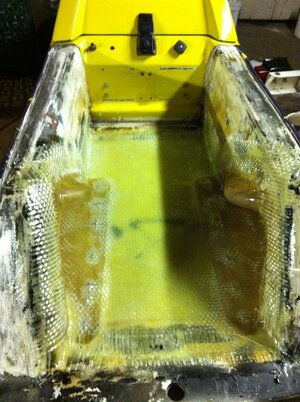

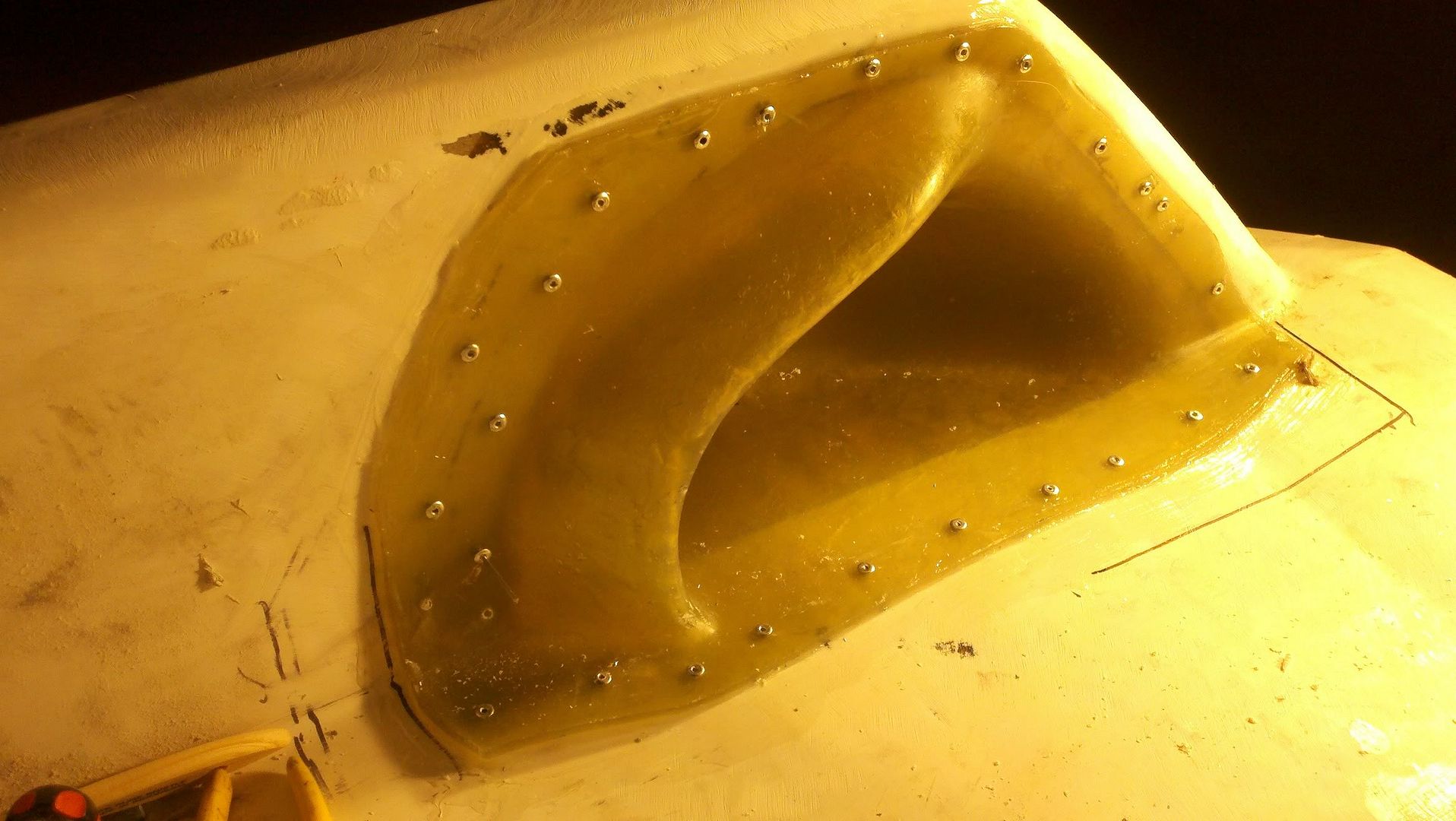

edit- jump to 2nd page. Im stuck. Pics are up

Page 3 lots of progress pics

I was hoping someone can point me to do a good how to write up on the install process. Also, all the materials ill need and if there's a place I can buy all the materials in one shot.

Thanks!

edit- jump to 2nd page. Im stuck. Pics are up

Page 3 lots of progress pics

Last edited: