Bobert540

Site Supporter

- Location

- Rockford,MI

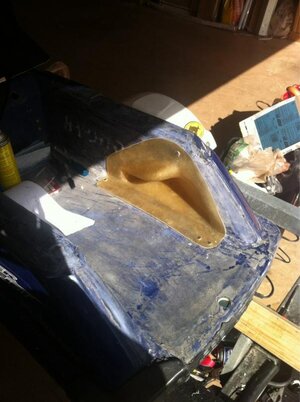

just rivet the bottom first. The holds will flex, then rivet the sides and top. Between the rivets and thickened epoxy they will sit in there fine. Then just follow up with glass, don't overthink it. You can do it!!