Hey guys,

Hoping to get a little feedback on my design before manufacture.

I've got a stock SJ650. It's my first ski and I'm having a blast on it. I ride on Loch Lomond, and it can get a bit rough, when the ski looses traction it's kind of like hitting the brakes, I've just rode a sx650 and an X2 with fancy intake grates and they didn't have the same issues, so after reading a little I'm assuming the stock grate is where the issue lies.

I have access to a metal laser cutter and a bunch of thin stainless plate, so thought I'd knock up a grate to try out. I'll post the files on here once I'm happy with the design in case anyone else wants to recreate it.

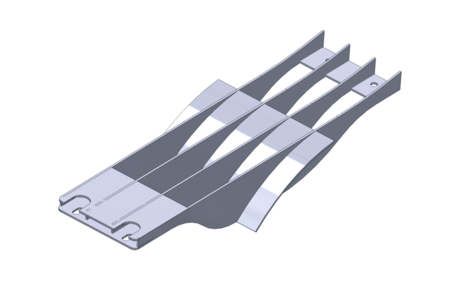

It's going to jigsaw together so be self jigging for welding. I'll 3d print some bits for around the ends to smooth out the lead ins. they'll be epoxied in later.

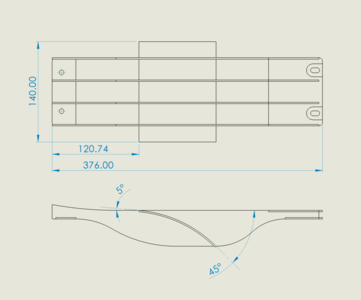

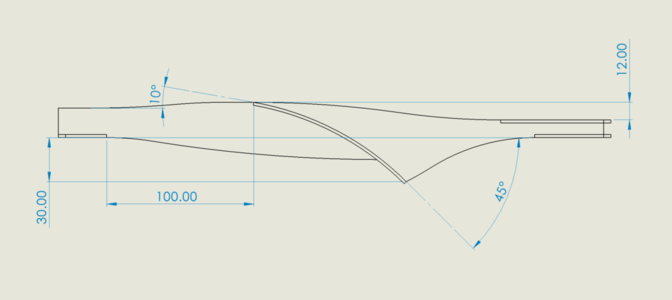

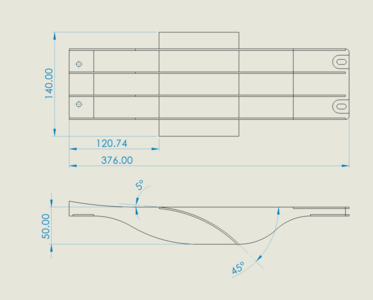

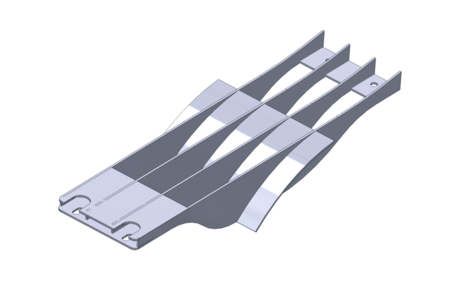

Overview of the concept

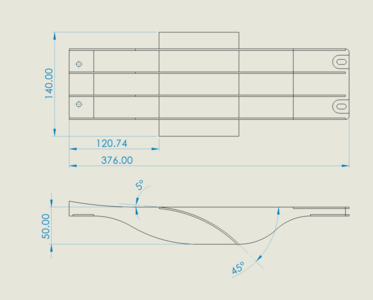

Rough dimensions of current concept

Intake is150mm wall to wall

Intake roof looks to be at roughly 45 degrees

90mm depth to driveshaft

I've just thrown the design together quickly, keen to get it made up before the weekend to test. All advice would be very welcome as I've no experience with this.

Thanks.

Hoping to get a little feedback on my design before manufacture.

I've got a stock SJ650. It's my first ski and I'm having a blast on it. I ride on Loch Lomond, and it can get a bit rough, when the ski looses traction it's kind of like hitting the brakes, I've just rode a sx650 and an X2 with fancy intake grates and they didn't have the same issues, so after reading a little I'm assuming the stock grate is where the issue lies.

I have access to a metal laser cutter and a bunch of thin stainless plate, so thought I'd knock up a grate to try out. I'll post the files on here once I'm happy with the design in case anyone else wants to recreate it.

It's going to jigsaw together so be self jigging for welding. I'll 3d print some bits for around the ends to smooth out the lead ins. they'll be epoxied in later.

Overview of the concept

Rough dimensions of current concept

Intake is150mm wall to wall

Intake roof looks to be at roughly 45 degrees

90mm depth to driveshaft

I've just thrown the design together quickly, keen to get it made up before the weekend to test. All advice would be very welcome as I've no experience with this.

Thanks.