Well, I was gonna get one of the alloy ones until I searched around on the forums a bit. It seems nobody sells one that fits correctly without modifications. In fact, most people seem to be disappointed with the part when they receive it. Then you ad in the fact that I am putting this on a blaster and all the alloy ones are designed for the sj. People 'say' they fit both (and some even say they use the exact same shoe) but the fact of the matter is the factory has different part numbers for pump shoes on the sj vs the blaster. I think I will trust the original engineers that these parts need to be unique. Smaller parts bin equals bigger profit so I think it's pretty safe to say these parts are different for a good reason. Really, the last thing I wanted to do was spend a bunch of money (and time) putting on a part that doesn't fit right just to end up right back where I was before, cavitation central.

Also, pretty much the biggest selling point of the alloy shoes is that once you start making big hp the stockers won't last. I bought this for a while until I looked into it more. Fact of the matter is, a number of aftermarket hull builders use the stock pump shoe on their boats. I think it's pretty safe to say these boats are built around the idea of BIG power. When confronted about this, I saw one manufacturer claim the stockers will stand up to a ton of hp and will only likely break if you hit something. Given I found a broken intake grate when I found my broken pump shoe, I have no doubt this is what happened with my rig.

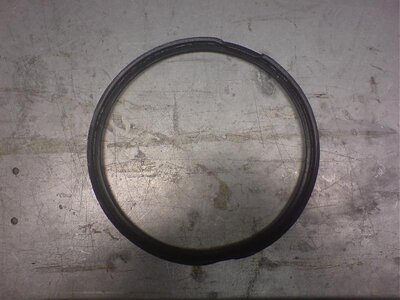

Big can of worms later, I picked up a stocker from parker for like $55.

:starwars: