You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Freestyle Bore Reduction Nozzle

- Thread starter Snivilous

- Start date

- Location

- Loveland, Colorado

Im getting mine done this winter. group k suggest that a 85 bore nozzel.

From what I have read here on the X. The standard nozzle can be bored to about 85, you can go larger supposedly using a gp800 nozzle. (I think it has to be a specific year) I am still trying to find people that have run that setup other than Lucas. I am not sure if most trim setups and steering nozzles work in that situation yet. If I find a gp800 setup cheap enough I may try it.

From what I have read here on the X. The standard nozzle can be bored to about 85, you can go larger supposedly using a gp800 nozzle. (I think it has to be a specific year) I am still trying to find people that have run that setup other than Lucas. I am not sure if most trim setups and steering nozzles work in that situation yet. If I find a gp800 setup cheap enough I may try it.

The GP800 nozzle will work with most trim setups with some modifications. It is shaped much differently than 62t nozzle and is harder to bore because it is offset.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

I bored a couple nozzles a few weekends ago and was looking for these same details. 84.5mm to 85mm seems to be the limit on oem stuff including the gp800 nozzle since that is what I bored out. I was able to go to 86mm on an aftermarket nozzle and still have plenty of material left.

I was way overpropped before so a drop in top speed was welcomed and the increase in bottom thrust was well worth it. I did find that I top out in speed now at just over half throttle but my impeller spacing was more than 3/8" and nowhere near ideal so I will hold my final opinion until I can try it again with my spacing correct. I thru my ski back together just to be able to ride with a couple things not quite right so it was definately not a very clean trial of what the boring mod really offers.

This is an inside view of a 62T Nozzle from a 97 GP800 bored out to 85mm and set on a Sato Engineering nozzle at a bore of 82.3mm

This is an outside shot of the same pairing just to show the difference in sidewall thickness.

I was way overpropped before so a drop in top speed was welcomed and the increase in bottom thrust was well worth it. I did find that I top out in speed now at just over half throttle but my impeller spacing was more than 3/8" and nowhere near ideal so I will hold my final opinion until I can try it again with my spacing correct. I thru my ski back together just to be able to ride with a couple things not quite right so it was definately not a very clean trial of what the boring mod really offers.

This is an inside view of a 62T Nozzle from a 97 GP800 bored out to 85mm and set on a Sato Engineering nozzle at a bore of 82.3mm

This is an outside shot of the same pairing just to show the difference in sidewall thickness.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

onedumbtrucker

Now with 20% more pulp.

- Location

- London, ON

Im running a mod701 with a skat 14/19 87mm nozzle. Works awesome. Tried 12/17 85mm and i like the new setup better.

Scotty, did you have the TBM and C-75 with the 85mm? I am also trying to decide what pump changes to make for next year to go with my new Jetmaniac motor.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

The basic reduction nozzle rules are; the larger the nozzle exit diameter, the greater the volume of water you can move. This is great for a freestyle bottom end and hole shots but the problem is that sometimes you do not have the proper exit velocity for top speed. The smaller the nozzle exit diameter, the greater the velocity of the water exiting, the better the top speed. The problem is that sometimes there is not enough volume of water to get the ski to top speed. It takes a blend of the two that gets both hole shot and top speed. If you have two different exit sizes or angles to compare, then one is more than likely better than the other and it takes testing to find out what works best with your setup. All the nozzles have a tapered exit angle and it is NOT recommended to bore them straight because it loses pump efficiency so the angle should be maintained if boring your nozzle. I'm sure each reduction nozzle that Yamaha develops is specifically engineered for their skis by the engine power to weight ratio, pump size, impeller type & pitch, hull design, top speed, drag etc. Most of their jet-ski’s with smaller displacement engines that weigh less use the steeper 25.5-degree reduction nozzle angles with varying nozzle exit tip angles. While the bigger ski’s that weigh more with the larger engine displacements use the 21-degree reduction nozzle angle with different nozzle exit angles and sizes. Some of their nozzles even use a bowl shape design with the nozzle exit angled upwards. Your hull can travel at radically different angles at different speeds depending on your ride plate, venturi angle and even how you're positioned on the ski. The steeper nozzle exit angles of 3.5-degrees or more will lighten the nose of the craft and may add top speed. While the shallower nozzle exit angles of 2.5-degrees or less will deliver improved performance in rough water conditions by producing more nose pressure to drive the hull through the bumps which is perfect for closed coarse and offshore competition race boats. Also a ski traveling at an angle of 2-degrees does not bring in the same amount of water into the intake tunnel as a ski traveling at 5-degrees at real high speeds. The faster the ski travels the greater its tendency to run flatter and use a smaller venturi. If you continue to try to run at 5-degrees, then you're going to run into the pump over stuffing problem and a bigger diameter venturi may be just what you need to process that extra volume of water coming into the intake. All these things need to be taken into consideration when using other reduction nozzles types with different angles and exit diameters.

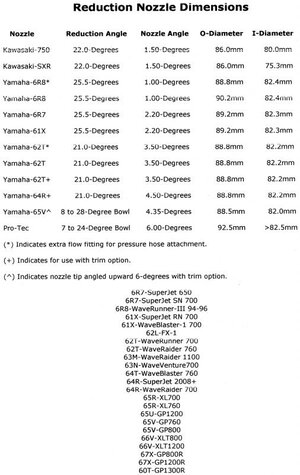

Here's a chart to see all the different angles and dimensions of the reduction nozzles.

Here's a chart to see all the different angles and dimensions of the reduction nozzles.

Attachments

Vumad

Super Hero, with a cape!

- Location

- St. Pete, FL

So PowerRanger told me that boring the reduction nozzle out helps bottom end and kills top end. Is this true? And how much bottom end punch would it increase?

yes and no. it's relative to the size of the prop and motor set up. If you ski has the right prop, then boring the nozzle will slightly improve the bottom and murder the top end. However, if you put a big motor and a big prop in a ski designed for smaller stuff, the right amount of bore can greatly improve bottom end with affecting the top end very little.

Tuning the pump is just like tuning the motor. All parts have to work together.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

Just to shed some light on the different reduction nozzles available, here are some I was working on today. I had already put the pump back in my ski or I would have had a pic of the Sato Engineering nozzle as well.

The black one is plastic and from a SN Superjet. The silver nozzle is from a 1997 GP760.

I found an old file pic of the Sato Engineering nozzle...

The black one is plastic and from a SN Superjet. The silver nozzle is from a 1997 GP760.

I found an old file pic of the Sato Engineering nozzle...

Last edited:

Ok boys let's play the nozzle game ...

Current set up :

Gomez LTD 701 bla bla bla . I was running a stock pump with a c75 12/17 (re pitched cut gold plated Gomez design ) 84 mm 61x reduction nozzle and It worked well . I had an older 8 vain mag pump I wanted to try so installed it and ran it at the lake. Test went well felt ,but felt like I lost a little punch off the bottom. I did a little surf ride this weekend and decided to install a 6R8 bored at 87 that is a 3 mill jump. I knew it would probably be to much but went with it. Never got it in the surf , but I did ride it in the river (Boyer had trouble long story..... don't want to thread jack my own thread ).

Observations :

First thing I noticed was I lost a good bit of punch ,but what I did not expect was that it really loosened up the handling ( which I liked ). The hull broke loose much easer with the 87mm 6r8 nozzle than with the 84mm 61x .

Question : why did the nozzle loosen up the handling ?

1 . Nozzle angle 61x @ 2.20 degree and 6r8 @ 1 degree

2. Loss of pump pressure / suction as a result of 87 mm nozzle

Goal : keep the low end punch , loosen up the ski and keep the hook up when I want it.

I was told by a semi reliable source that when he swapped nozzles from a 61x to 62t same dia that the 62t made his ski break loose easer as well.

Current set up :

Gomez LTD 701 bla bla bla . I was running a stock pump with a c75 12/17 (re pitched cut gold plated Gomez design ) 84 mm 61x reduction nozzle and It worked well . I had an older 8 vain mag pump I wanted to try so installed it and ran it at the lake. Test went well felt ,but felt like I lost a little punch off the bottom. I did a little surf ride this weekend and decided to install a 6R8 bored at 87 that is a 3 mill jump. I knew it would probably be to much but went with it. Never got it in the surf , but I did ride it in the river (Boyer had trouble long story..... don't want to thread jack my own thread ).

Observations :

First thing I noticed was I lost a good bit of punch ,but what I did not expect was that it really loosened up the handling ( which I liked ). The hull broke loose much easer with the 87mm 6r8 nozzle than with the 84mm 61x .

Question : why did the nozzle loosen up the handling ?

1 . Nozzle angle 61x @ 2.20 degree and 6r8 @ 1 degree

2. Loss of pump pressure / suction as a result of 87 mm nozzle

Goal : keep the low end punch , loosen up the ski and keep the hook up when I want it.

I was told by a semi reliable source that when he swapped nozzles from a 61x to 62t same dia that the 62t made his ski break loose easer as well.

Last edited:

bump... it got buried