oxnard111

Creative RE Purchasing

- Location

- so Cali, Ventura/Oxnard area

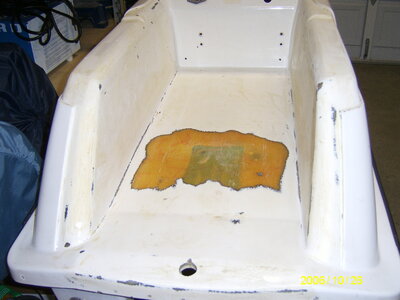

So I picked this puppy up to start working on. Its a 98. This is an ex race boat. Used to have a dry pipe of some sort on it b/c the lip where the hood seal is kinda cracked and will need to be repaired. The ski has Tubbie II's, I believe from what other have told me. The ski has no cracks or deep guages. My plan is to make a good surf boat. I am not pro or have huge balls so this boat wont get crazy trashed but never the less I want to atleast do some light reinforcing while she is still emtpy. I am planning on doing everything I want to boat except for paint, but we'll see if I don't paint it this winter; when I get finished I'll take everything out of my 97 SJ and then I'll re-sell the 97 hull. Here is a tentative list of what I want to do with the boat.

- Light Reinforcment (handlepole bracket, nose, side walls, bulk head and bottom)

- Take off the hull extensions that came on the ski and clean up those areas

- Cut down the long ass screws that are holding on the tubbies

- Install the Wamilton Rickters I already have

- D-Cut/Half Moon the stock ride plate I picked up off ebay for $4

- Possibly cut down the pole and inch or two

- Purchase and install a stubby pump come of one brand or another

- This list will continue

Here are some pictures of the ski the day after I picked it up. There are couple other random pictures. The picture of the pump area is showing the 5 different holes. Two cooling lines, stock bilge, steering cable, and drop nozzle.

- Light Reinforcment (handlepole bracket, nose, side walls, bulk head and bottom)

- Take off the hull extensions that came on the ski and clean up those areas

- Cut down the long ass screws that are holding on the tubbies

- Install the Wamilton Rickters I already have

- D-Cut/Half Moon the stock ride plate I picked up off ebay for $4

- Possibly cut down the pole and inch or two

- Purchase and install a stubby pump come of one brand or another

- This list will continue

Here are some pictures of the ski the day after I picked it up. There are couple other random pictures. The picture of the pump area is showing the 5 different holes. Two cooling lines, stock bilge, steering cable, and drop nozzle.