jetski9010

Team RTYD

- Location

- Lancaster PA

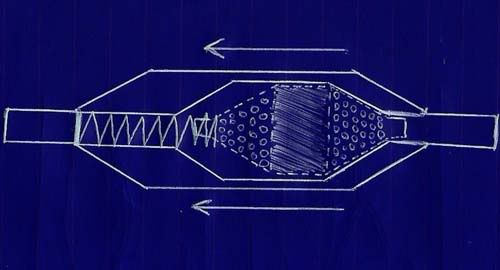

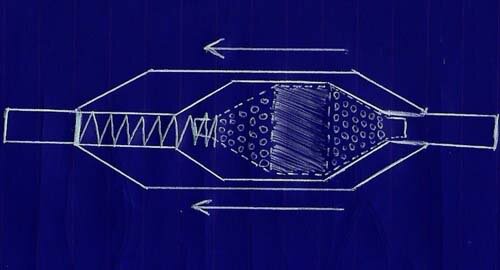

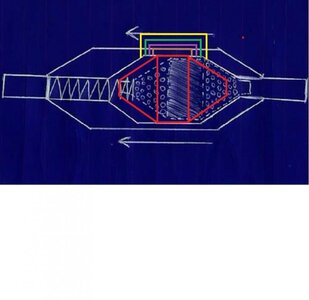

I found this while searching around on youtube. Do you guys think something like this could be made to work for a jet ski or can you already get enough change in the sonic wave speed from just injecting water or restricting water?

Last edited by a moderator: