ATS_Aaron

X-

- Location

- Shady Shores, TX

This thread is really for ATS_Scott, but he is trapped with his wife at Ikea right now so he can't ask.

We ride 99% flat water. Over the winter he Sport Ported a 650 6m6 motor and then at the last minute decided to bore it to a 701. It ran well, but he yearned for more power.

I recently bought a pair of old race skis, one was a limited ski and the other was a Super Stock/Modified ski. Scott wanted more power so we dropped the Super Stock/Modified motor in his ski. Here are the mods (that we know of):

MSD total loss ignition

Protec billet head with 3 bolt girdle

61X cylinder bored to 84mm

WPS (we think) pistons

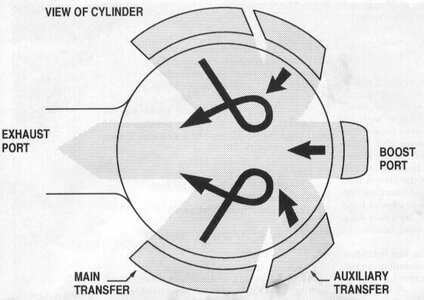

very, very ported

62T cases also very ported to match the cylinder/sleeves

R&D intake manifold

C/F reeds with stuffers

reed spacer

Big 48mm carbs

In the race ski it was using a type 4 dry pipe with water injection, but Scott installed it with his B-pipe using the old 650 (small) chamber.

So we rode it last weekend. It seems like the carbs are set up really well, but the ski has no bottom end. You pin it and it goes, goes, then HITS and I mean arm yanking HIT. The delay in the HIT has totally screwed up Scott's timing for jumps or tricks.

So in search of some better bottom end Scott pulled the cylinder yesterday to look at the porting. He measured from the top of the deck down to the top of the exhaust port and came up with 33mm. Are the exhaust ports too high for freestyle?

Is the carb size a problem for freestyle?

He took pics and will post them when he breaks free of Ikea.

Thanks in advance,

Aaron

We ride 99% flat water. Over the winter he Sport Ported a 650 6m6 motor and then at the last minute decided to bore it to a 701. It ran well, but he yearned for more power.

I recently bought a pair of old race skis, one was a limited ski and the other was a Super Stock/Modified ski. Scott wanted more power so we dropped the Super Stock/Modified motor in his ski. Here are the mods (that we know of):

MSD total loss ignition

Protec billet head with 3 bolt girdle

61X cylinder bored to 84mm

WPS (we think) pistons

very, very ported

62T cases also very ported to match the cylinder/sleeves

R&D intake manifold

C/F reeds with stuffers

reed spacer

Big 48mm carbs

In the race ski it was using a type 4 dry pipe with water injection, but Scott installed it with his B-pipe using the old 650 (small) chamber.

So we rode it last weekend. It seems like the carbs are set up really well, but the ski has no bottom end. You pin it and it goes, goes, then HITS and I mean arm yanking HIT. The delay in the HIT has totally screwed up Scott's timing for jumps or tricks.

So in search of some better bottom end Scott pulled the cylinder yesterday to look at the porting. He measured from the top of the deck down to the top of the exhaust port and came up with 33mm. Are the exhaust ports too high for freestyle?

Is the carb size a problem for freestyle?

He took pics and will post them when he breaks free of Ikea.

Thanks in advance,

Aaron