This was posted by Harry Klem from Group K in December of 2020 in a Facebook Group

A very important issue to all GP800 and GPR1200/1300 Owners

At Group K, we continue to work on “only” 2-stroke pwc engine platforms…. And we do a lot of them. Anytime we assemble an engine in-house, it is standard procedure for us to “pressure test” the assembled engine to assure there are no air leaks. Doing this pressure test assures that there are no air-leaks (that can result in difficult starting, erratic idling, and random lean conditions that can easily deliver a seized piston when operated at high rpm).

Over the years, we have seen the GP800 and GPR1200 engines be particularly susceptible to developing air leaks at the rear crank seals. What makes this disconcerting is that both of these engines have two rear crank seals, and failing both rear crank seals to result in an airleak “should be” very uncommon …. But it’s not.

We recently assembled a freshly rebuilt GPR1200 motor for a customer, and when we pressure tested it, It had a “huge” visible airleak at the ID of the brand new real crank seal we installed ….. and we realized that both of the new crank-seals we had installed had to be leaking in the same grandiose way …. And that is just not supposed to happen.

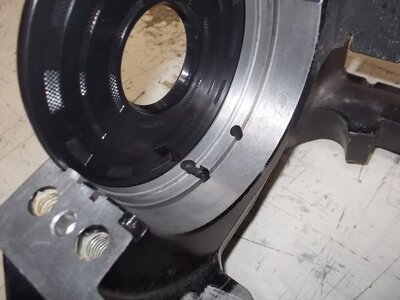

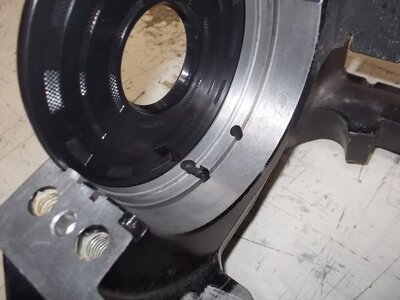

With that, we removed the bottom case of the assembled engine to find the source of the air leak. To help understand what was happening, we then re-assembled the engine with only the inner rear crank seal in place to we could see the source of it’s leak. What we saw was something between frightening and humbling.

As we pressurized the motor with only one rear crank seal installed, we saw that air was leaking out of the engine faster than we could put air in. We quickly realized that a “cast-in” oil galley in the top case (meant to bring oil in between the two rear seals) was completely bypassing the inner rear crank seal …. Thus making this inner-rear crank seal 100% useless and without purpose. This meant that the single-spring outer crank seal next to the drive coupler was the only seal offing any sealing properties at all for this engine. It bears noting that ALL valved GP800 and GPR1200/1300 engines have exactly this same defective feature.

The only solution for this problem was to fill the offending galley with a high quality epoxy, and then dress the hardened epoxy down to match the machined seal holding surface of the case … and we do so.

Afterwards, we once again pressure tested the engine with only the “inner rear” crank seal …. Instead of leaking air out faster than we could put it in, the engine held 8+psi perfectly.. problem solved. Obviously, the outer crank seal would now just be a failsafe luxury. We applied a generous amount of dielectric grease between the two rear seals before final assembly (as we have done with 440/550 jetski engines for decades) … and it was all good.

Afterwards, we reflected back on the countless GP800/1200/1300 engines over the last 22 years, that we had worked with that had experienced “random” rear cylinder failures for no apparent reason…….. and found ourselves at a lack for words why we had never noticed this defect earlier….. sorry about that.

The good news is that none of the earlier “un-valved Yamaha 633-1200 engines share this same defect.

The easiest method for filling with Epoxy was discovered by Christian Morris.

When filling the second hole for the rear seal in crankcase, I have found tapping it first to be the best route to go to provide mechanical interference for the epoxy to bite into