- Location

- Winnipeg, Canada

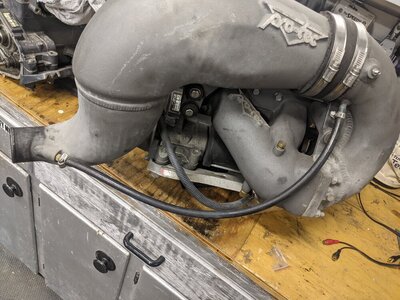

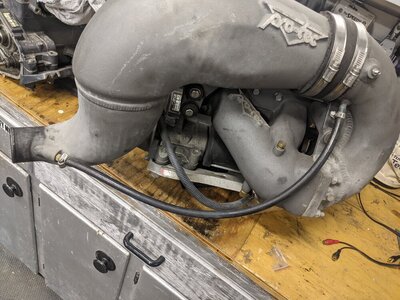

Hey guys, maybe I just suck at looking things up, but I can't find much info about the Protec pipes in regards to what each of the 2 adj. screw on the head pipe do, what a good starting point is for them, temp to run the pipe at (or even where to measure) or just tuning info in general. Forgive my ignorance, I'm learning...

Ps: the setup runs good, I didn't tune it, just want to understand/learn how to run it for optimal performance.

Ps: the setup runs good, I didn't tune it, just want to understand/learn how to run it for optimal performance.