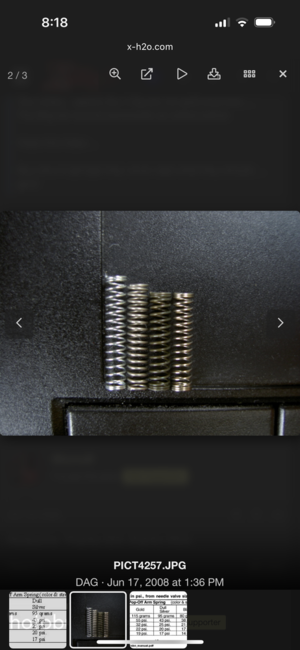

Measure the pop-off pressure, then look-up your Spring in the Mikuni Chart along the 1.5 Needle Valve Size row.

You need to do the Pop-off tests anyway to check for leaks and to know what it is.

Stock OEM Jets are #70 and #135 for Sea Level.

Factory Pipe Type 4 Dry Pipe Jets are #75 and #140 with Stock OEM N&S for Sea Level.

The High Elevation reduction in Oygen, which leads to a Rich Condition with Sea Level settings, can be accounted for by turning in the Carb Adjustment Screws as needed.

Use a Tachometer for Tuning.

The Pop-Off might need to be slightly lower than spec'd for Sea Level, since the higher altitude atmospherice pressure is slighlty lower than at Sea Level, thus the Needle Valve opening a little later for the Spring being slighlty too "strong" to be overcome by the Atmospheirc pressure.

Because the Needle Valve Spring is opposed by the Regulator Diaphragm and the Regulator Diaphragm is "pushed" by Atmospheric Pressure.

Short story, adjust Low Speed Screws until a crisp snappy response is obtained fron Idle to WOT when kneeling on the Tray at Idle. I call it the "Whiplash Test."

If it hesitates or even dies, the Low Speed is Lean, so OPEN the Low Speed Screws. If it gurgles, loads up or responds "dirty", then it's Rich so turn the Low Speeds IN. Make the adjustments 1/8 of a Turn at a time.

Make sure you're synhcronizing or turning them IN or OUT the same in both Carbs. Too easy to forget or get distracted when turning Screws. Many People will turn one Carb one way and go the other way on the other Carb by mistake. Happens more often than you would think.

Pre-set the Carb Screws on the Bench so you start from known Turn Settings.

The more Advanced Tuners will adjust each Carb individually by treating each Cylinder as an independent Engine. But that's another Story.

Make sure the Throttle Butterflys are synchronized after you install them. Adjust until the Butterflyes are dead even. Eyeball is good; ************ Gap Gauge even better.

Odd how the Word F-E-E-L-E-R is not allowed...