You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SJ compression

- Thread starter wishihad

- Start date

Mike W

Infidel

- Location

- North Florida

It might be your gauge. Try another one. Make sure its tight in the spark plug hole and not letting air escape.

aqua

the taco

- Location

- Jefferson City, MO

with the fresh hone you wont get as good of compression until it all seats in.

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

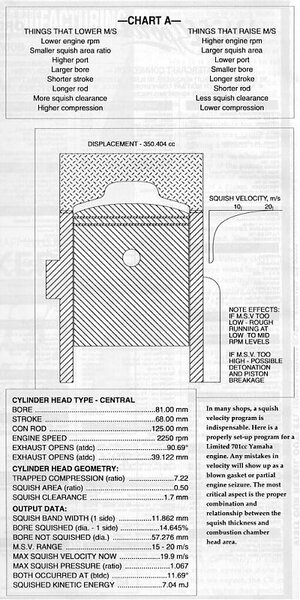

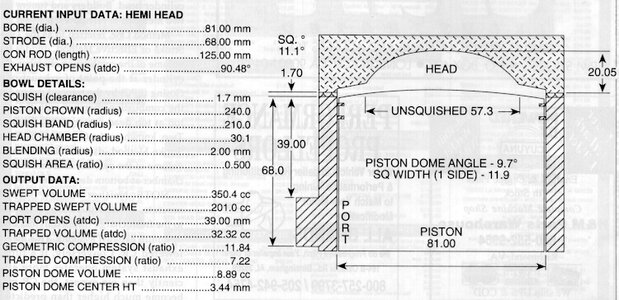

I like using the solder method because you can also check the bending radius of your squish band. If you want to really do it correctly remove the head and place four pieces of solder at 12,3,6,9 o'clock intervals pointing toward piston center, retorque the head down as if you were putting it together to run. With the piston just slightly before tdc rotate the crank till the piston rotates through tdc and stop. Take the head off, measure the thinnest portions of the solder. The reason you measure all 4 is because if you're at tolerance at on side you may be over at other side.

Attachments

I like using the solder method because you can also check the bending radius of your squish band. If you want to really do it correctly remove the head and place four pieces of solder at 12,3,6,9 o'clock intervals pointing toward piston center, retorque the head down as if you were putting it together to run. With the piston just slightly before tdc rotate the crank till the piston rotates through tdc and stop. Take the head off, measure the thinnest portions of the solder. The reason you measure all 4 is because if you're at tolerance at on side you may be over at other side.

Now you're talking! Thanks!! Awesome info!!!!!!!:arms:

So if I want to take the easy path can I:

1. Rotate the engine so it's a few degrees before TDC

2. Insert a piece of soilder thru the plug hole so that it just reaches the cylinder wall.

3.Rotate the motor thru TDC (by hand!)

4. Then carefully remove the solider and measure the thinnest part of the squished section of the soilder.

And assuming it's around 1.7mm all should be good mechanically.

Correct??

Thanks!

1. Rotate the engine so it's a few degrees before TDC

2. Insert a piece of soilder thru the plug hole so that it just reaches the cylinder wall.

3.Rotate the motor thru TDC (by hand!)

4. Then carefully remove the solider and measure the thinnest part of the squished section of the soilder.

And assuming it's around 1.7mm all should be good mechanically.

Correct??

Thanks!

#ZERO

Beach Bum

- Location

- Florida - U.S.A.

Yes… that method will work okay but you need to insert the solder parallel with the wrist pins because the pistons have excessive clearance when the engine is cold.

- Location

- Gtown,Tejas

Whats your ring gaps look like??? What about piston tolerences??

I see in the first post you checked it,but just want to make sure. What about the cylinders? are they up to spec?

Just trying to help

Good Luck

I just tested mine on a bone stock new ski with about 10 tanks ran through it and I had 165lbs. front 163lbs rear.

I see in the first post you checked it,but just want to make sure. What about the cylinders? are they up to spec?

Just trying to help

Good Luck

I just tested mine on a bone stock new ski with about 10 tanks ran through it and I had 165lbs. front 163lbs rear.

Last edited: