OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

This will be a work in progress that can be added to the tech section once fully fleshed out.

I pulled my ADA steering system apart to measure the size of the O-rings for @Big Kahuna and found that my system needed some attention as well.

http://adaracing.com/super-jet-sealed-steering-system/

The rebuild is easy enough. Just clean everything really well and reassemble with new parts. The trick is finding the right parts and maybe sourcing some better ones to avoid the rusting bearings in the future.

It doesn't exist yet but it's been pitched to Neil @RMBC Freeride to possible develop a tuff-thrust washer setup for these like he did for the Yamaha and RRP systems.

http://www.x-h2o.com/index.php?thre...ild-kits-rrp-tuff-thrust.152296/#post-1938674

The following should make things easier for other's in the same situation. All parts are available through McMaster-Carr.

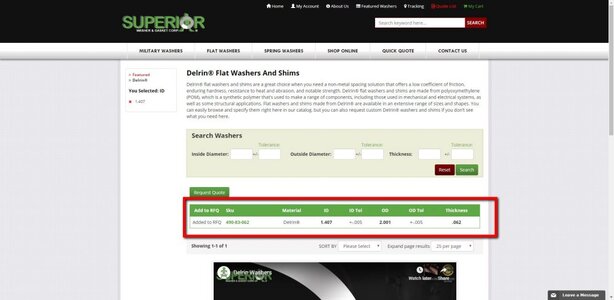

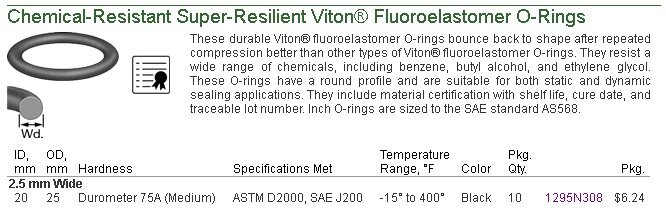

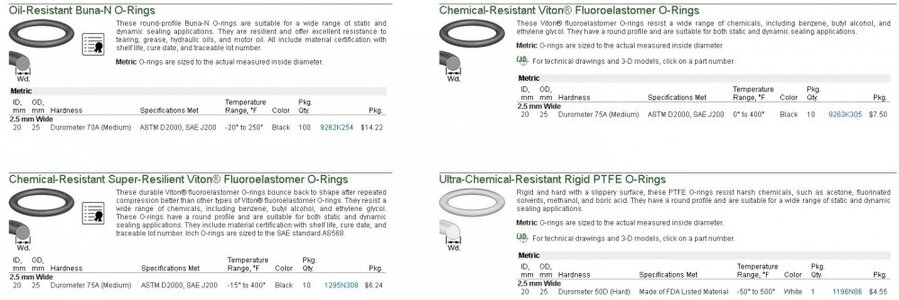

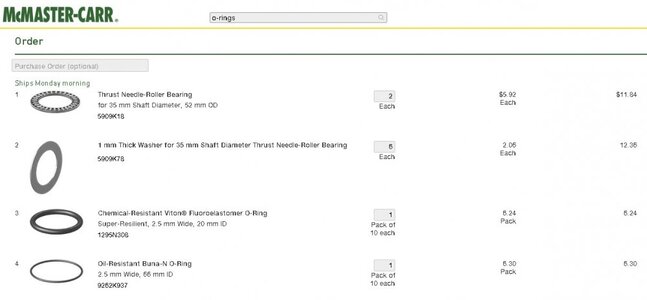

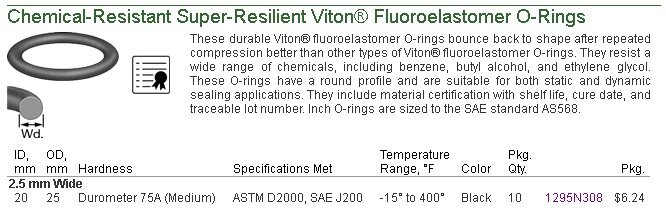

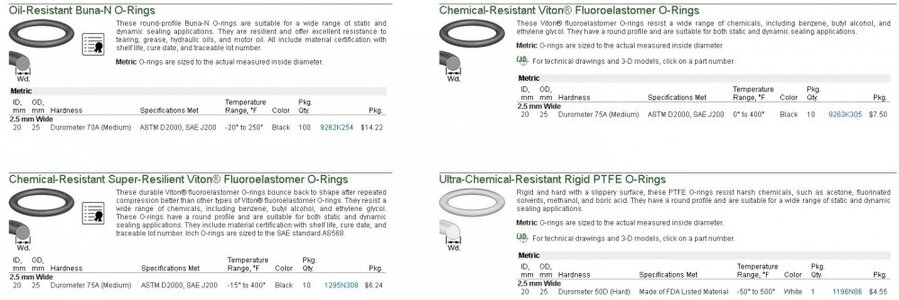

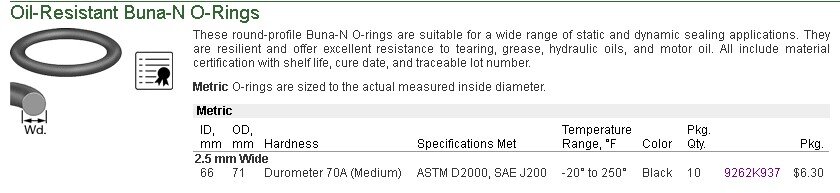

Small O-ring (1 needed);

- Thickness = 2.62 mm

- ID = 20 mm

- OD = 25 mm

- McMaster Part # = 1295N308 (Pk of 10 @ $6.24)

I could have chosen the standard Oil-resistant Buna-N O-rings but I don't need 100 kicking around the house for $14.22 when I can get 10 for $6.24.

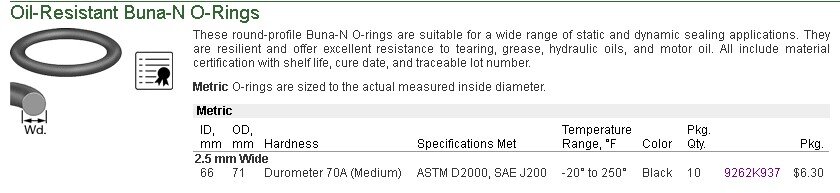

Large O-ring (2 needed);

- Thickness = 2.62 mm

- ID = 66.5 mm

- OD = 71.5 mm

- McMaster Part # = 9262K937 (Pk of 10 @$6.30)

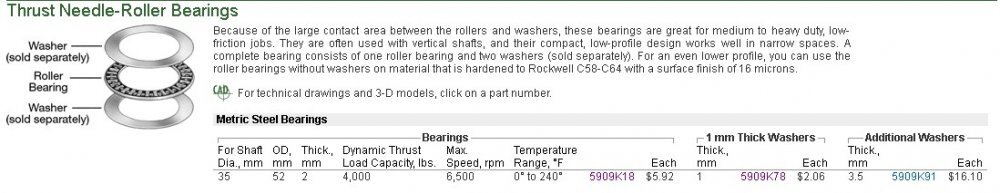

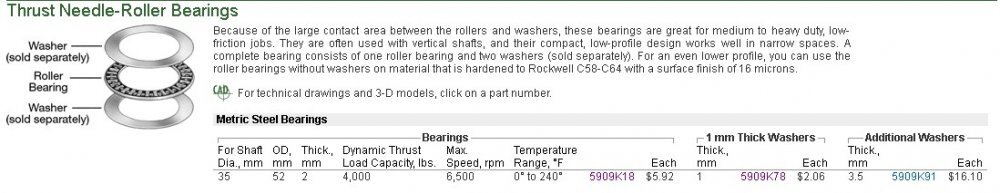

Thrust Needle Roller Bearing (2 needed);

- Thickness = 0.0785"

- ID = 35.5mm

- OD = 2.0380"

- McMaster Part # 5909K18 (Bearing, 2 needed @ $5.92 each)

5909K78 (1 mm washer, 4 needed @ $2.06)

5909K91 (3.5 mm washer, optional if required @ $16.10 each)*

* My steering plate is slightly thinner and I had some play so I ordered a couple extra 1 mm washers so I can make some adjustments.

https://www.mcmaster.com/#standard-rolling-element-thrust-bearings/=18fahgd

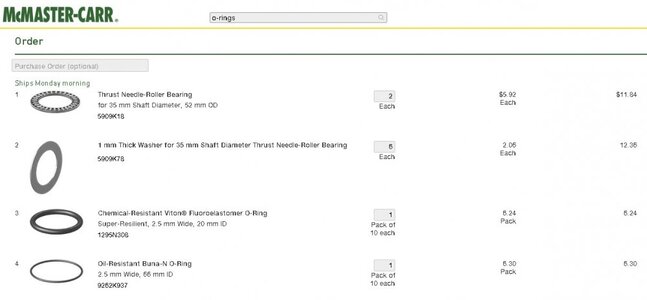

The Total comes to $36.74 to rebuild 1 system or $56.82 for 2. (plus taxes and shipping)

My Hardware was re-useable but if you need new stuff;

Stainless Hardware (316 Stainless);

- M6 Flat Head Socket Screw = 93395A363 (Pk of 25 @ $10.62)

- M6 Flat Washer = 94205A250 (Pk of 50 @ $6.52)

- M6 Nylon Locking Nut = 90965A170 (Pk of 100 @ $6.86

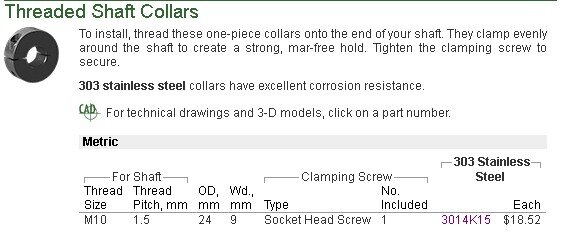

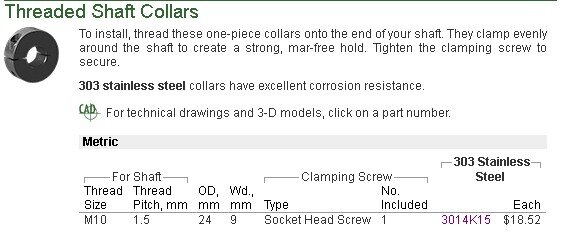

Locking Collar (I ditched the bolt for a stud and locking collar on my setup);

- M10 Threaded Shaft Collar = 3014K15

I pulled my ADA steering system apart to measure the size of the O-rings for @Big Kahuna and found that my system needed some attention as well.

http://adaracing.com/super-jet-sealed-steering-system/

The rebuild is easy enough. Just clean everything really well and reassemble with new parts. The trick is finding the right parts and maybe sourcing some better ones to avoid the rusting bearings in the future.

It doesn't exist yet but it's been pitched to Neil @RMBC Freeride to possible develop a tuff-thrust washer setup for these like he did for the Yamaha and RRP systems.

http://www.x-h2o.com/index.php?thre...ild-kits-rrp-tuff-thrust.152296/#post-1938674

The following should make things easier for other's in the same situation. All parts are available through McMaster-Carr.

Small O-ring (1 needed);

- Thickness = 2.62 mm

- ID = 20 mm

- OD = 25 mm

- McMaster Part # = 1295N308 (Pk of 10 @ $6.24)

I could have chosen the standard Oil-resistant Buna-N O-rings but I don't need 100 kicking around the house for $14.22 when I can get 10 for $6.24.

Large O-ring (2 needed);

- Thickness = 2.62 mm

- ID = 66.5 mm

- OD = 71.5 mm

- McMaster Part # = 9262K937 (Pk of 10 @$6.30)

Thrust Needle Roller Bearing (2 needed);

- Thickness = 0.0785"

- ID = 35.5mm

- OD = 2.0380"

- McMaster Part # 5909K18 (Bearing, 2 needed @ $5.92 each)

5909K78 (1 mm washer, 4 needed @ $2.06)

5909K91 (3.5 mm washer, optional if required @ $16.10 each)*

* My steering plate is slightly thinner and I had some play so I ordered a couple extra 1 mm washers so I can make some adjustments.

https://www.mcmaster.com/#standard-rolling-element-thrust-bearings/=18fahgd

The Total comes to $36.74 to rebuild 1 system or $56.82 for 2. (plus taxes and shipping)

My Hardware was re-useable but if you need new stuff;

Stainless Hardware (316 Stainless);

- M6 Flat Head Socket Screw = 93395A363 (Pk of 25 @ $10.62)

- M6 Flat Washer = 94205A250 (Pk of 50 @ $6.52)

- M6 Nylon Locking Nut = 90965A170 (Pk of 100 @ $6.86

Locking Collar (I ditched the bolt for a stud and locking collar on my setup);

- M10 Threaded Shaft Collar = 3014K15

Last edited: