Another reason could be the oil used with the piston rings when motor is assembled. Engine needs to be run on the water with a load then checked with a compression gauge after running in.

Thanks for the feedback. Yes, I'm aware of this...motor has been tested dozens of times in the field at operating temps. I've even "washed" cylinder walls with plain gas (then air dried) in order to eliminate oil viscosity boost.

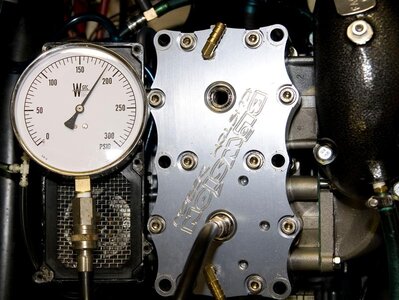

Today I might go out and buy an industrial "lab" spec (1% full sweep) gauge (at Grainger) and put it on my standard compression gauge connectors. Because of the different reading depending on what/whos gauge I was using (5 gauges between 190-215 psi), I want to completely eliminate a bogus gauge.

Ran ski again yesterday and it runs so good, cool and without any engine noises. While I know what/how to listen for detonation on a 4-stroke, I don't think I've even been able to hear it on a 2-stroke. Would a billet dome get pitted or show signs or is the billet too hard for that to happen? Pistons are too clean to show anything.