You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OEM style airboxes for 44/46 and aftermarket carbs

- Thread starter joeschuit

- Start date

- Location

- Long Beach, CA

That's too cheap, I think your number should be at least $150.00 for the pair. That's a great product. I paid 180.00 for some rear sponsons that look like a 12 YO made them. 2 used SN airboxes (hard to find now) and the adapter bases for modded carbs will set you back 250.00+shipping.

- Location

- Spring Lake, MI

I think in a retail setting with money invested in a more refined product, pricing them in the $150 range would probably be reasonable. I know most still look at printed parts much differently than injection molded plastic, and for good reason. These would be cool to have injection molded like a powertool clamshell. Glass fiber reinforced nylon or whatever similar to yamaha oem airboxes. The long-term lifespan of this stuff is still unknown and I'm doing my best to make something that should last a few years and save a few engines from water induced deaths. Being able to make small changes either for a new gen version or for individual customers is very handy.

Time to gush over quality hose clamps. From mcmaster for only $2.60 a piece, you get a norma brand hose clamp from Germany. 304 stainless everything, rolled edges, and the smoothest turning clamp I've ever used. Purchased a new set of novi 48mm carbs and found the carb tops to be a bit different than the dasa/full spec/se carb tops I've seen. About 5mm taller, 0.5mm bigger in diameter, and a 0.25mm step about halfway down. I made a separate base that fits these well. However, I had to mill about 2.5mm of a flange that gets in the way of the hose clamp. Not a big deal for me but the alternative is only seating 2/3rds of the way down and trying to make that work. Now that I have the correct clamps in I'll be making the final design changes and getting some printed. In the next couple weeks I'll be attempting to make a poor mans flow bench for testing some of these bases and covers. More or less an arduino nano to convert an analog 0-5volt mass airflow sensor data to cfm on an lcd screen. By no means will it be accurate but it will be precise and repeatable. My big concern is if there is a restriction using the low profile airbox covers and how these airboxes compare to the industry standard "cone filters" being used right now. Stay tuned.

Time to gush over quality hose clamps. From mcmaster for only $2.60 a piece, you get a norma brand hose clamp from Germany. 304 stainless everything, rolled edges, and the smoothest turning clamp I've ever used. Purchased a new set of novi 48mm carbs and found the carb tops to be a bit different than the dasa/full spec/se carb tops I've seen. About 5mm taller, 0.5mm bigger in diameter, and a 0.25mm step about halfway down. I made a separate base that fits these well. However, I had to mill about 2.5mm of a flange that gets in the way of the hose clamp. Not a big deal for me but the alternative is only seating 2/3rds of the way down and trying to make that work. Now that I have the correct clamps in I'll be making the final design changes and getting some printed. In the next couple weeks I'll be attempting to make a poor mans flow bench for testing some of these bases and covers. More or less an arduino nano to convert an analog 0-5volt mass airflow sensor data to cfm on an lcd screen. By no means will it be accurate but it will be precise and repeatable. My big concern is if there is a restriction using the low profile airbox covers and how these airboxes compare to the industry standard "cone filters" being used right now. Stay tuned.

Attachments

- Location

- Spring Lake, MI

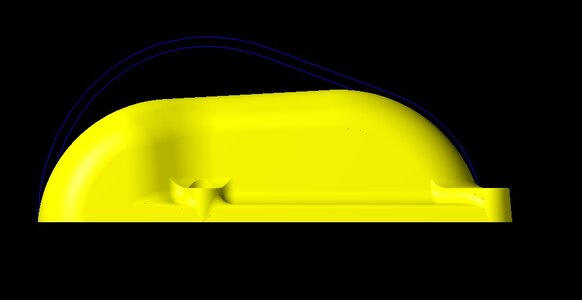

The design was finalized and sent a couple sets out. I'm really liking the new design and should eliminate almost all of the shortfalls of the previous single pinch bolt style. The flowbench is mostly done and has been tested with single and twin vacuums. I've got a digital manometer coming tomorrow so the negative pressure can be read and kept consistent for correct cfm readings. I've got a few different airboxes to test, including a new tall profile airbox cover prototype that has about 50% more surface area. It's 20mm taller than the low profile cover but still keeps it low towards the back edge where there's usually interference with the hull/hood opening edge.

Attachments

-

PXL_20250317_120224681.jpg132.4 KB · Views: 55

PXL_20250317_120224681.jpg132.4 KB · Views: 55 -

PXL_20250307_174558431.jpg189.7 KB · Views: 52

PXL_20250307_174558431.jpg189.7 KB · Views: 52 -

airbox.jpg33.6 KB · Views: 52

airbox.jpg33.6 KB · Views: 52 -

PXL_20250317_120213550.jpg101.6 KB · Views: 50

PXL_20250317_120213550.jpg101.6 KB · Views: 50 -

PXL_20250312_174029881.jpg113.9 KB · Views: 45

PXL_20250312_174029881.jpg113.9 KB · Views: 45 -

PXL_20250312_174015479.MP.jpg87.9 KB · Views: 47

PXL_20250312_174015479.MP.jpg87.9 KB · Views: 47 -

PXL_20250312_173733909.jpg156.2 KB · Views: 43

PXL_20250312_173733909.jpg156.2 KB · Views: 43 -

PXL_20250310_115952822.jpg152.4 KB · Views: 44

PXL_20250310_115952822.jpg152.4 KB · Views: 44 -

PXL_20250309_221348824.jpg142.1 KB · Views: 57

PXL_20250309_221348824.jpg142.1 KB · Views: 57

Quinc

Buy a Superjet

- Location

- California

Looks awesome! Looking forward to seeing your results.

- Location

- Spring Lake, MI

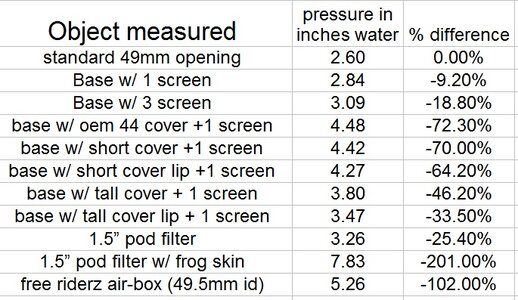

Making good progress on the flowbench and have been working on an added feature that I can incorporate. A dual vacuum attachment has been designed and printed. Quickly blew a breaker. Will probably purchase a ridgid 6.5hp with detatchable blower top that I can mount onto a custom box for a good compromise in a single vacuum source. What I've found is it's difficult to get a consistant cfm reading from the maf sensor. However, I can get a good vacuum pressure from the digital manometer. So what I've been doing is keeping the vacuum at 100% power and comparing the pressure difference between each filter combo. Put simply, if I see a rise in positive pressure(lower vacuum pressure) then I know there's less restriction and thus capable of higher flow. My current vacuum isn't all that powerful, but I can still see and feel the difference between the different filters. The biggest difference is adding a bellmouth at the cover opening. I'm printing one of my low profile covers with this for testing. Numbers below are just for reference, but show what I'm currently dealing with. The pod filter is a bit shorter than standard. The frog skin cover on the pod filter are a huge restriction, didn't get numbers though. Big numbers bad, small numbers good. all in inches of water.

novi 48 bare: 3.04

Novi 48 with base and 1 screen: 3.14

oem square cover: 4.40

low profile cover: 4.28

tall cover with bellmouth: 3.62

Pod filter: 3.50

novi 48 bare: 3.04

Novi 48 with base and 1 screen: 3.14

oem square cover: 4.40

low profile cover: 4.28

tall cover with bellmouth: 3.62

Pod filter: 3.50

Attachments

WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

I looked into having some stuff made from injection molded glass reinforced nylon one time, the problem is that product is really tough on the molds so they have to be made from hardened steel and then it costs a small fortune to have the molds made , the guy I talked to wouldn't even make them he said he gets those type molds made in China so he can get a reasonable price on them.I think in a retail setting with money invested in a more refined product, pricing them in the $150 range would probably be reasonable. I know most still look at printed parts much differently than injection molded plastic, and for good reason. These would be cool to have injection molded like a powertool clamshell. Glass fiber reinforced nylon or whatever similar to yamaha oem airboxes. The long-term lifespan of this stuff is still unknown and I'm doing my best to make something that should last a few years and save a few engines from water induced deaths. Being able to make small changes either for a new gen version or for individual customers is very handy.

Time to gush over quality hose clamps. From mcmaster for only $2.60 a piece, you get a norma brand hose clamp from Germany. 304 stainless everything, rolled edges, and the smoothest turning clamp I've ever used. Purchased a new set of novi 48mm carbs and found the carb tops to be a bit different than the dasa/full spec/se carb tops I've seen. About 5mm taller, 0.5mm bigger in diameter, and a 0.25mm step about halfway down. I made a separate base that fits these well. However, I had to mill about 2.5mm of a flange that gets in the way of the hose clamp. Not a big deal for me but the alternative is only seating 2/3rds of the way down and trying to make that work. Now that I have the correct clamps in I'll be making the final design changes and getting some printed. In the next couple weeks I'll be attempting to make a poor mans flow bench for testing some of these bases and covers. More or less an arduino nano to convert an analog 0-5volt mass airflow sensor data to cfm on an lcd screen. By no means will it be accurate but it will be precise and repeatable. My big concern is if there is a restriction using the low profile airbox covers and how these airboxes compare to the industry standard "cone filters" being used right now. Stay tuned.

DylanS

Gorilla Smasher

- Location

- Lebanon Pa

super cool what you got going on here. Dig the home testing setup.

- Location

- Spring Lake, MI

Starting to sound like an intro to an infomercial for a new kitchen gadget or miracle cleaner. Yes, what I'm seeing is there are so many different hulls, engines, carbs, etc that right now different height pod filters are the only "long term" solution for hull and hood clearance. Although it seems longevity out of stainless mesh and adhesive could be a few rides to a few seasons. This season will be a real test of the new clamping design. I've got a half dozen mailed out already and will have them on both my personal ski and a couple other local's skis. I've got a more comprehensive list of airboxes tested. I should have a 2" pod filter I can borrow for testing. I've thought about flow vs horsepower when it comes to these things and at what point does a bigger box stop increasing performance. Best I can come up with so far from an oem standpoint is the 61x 701 with a single 44 and square box flame arrestor. It made 63 hp with that flame arrestor and I'm somewhat confident that isn't the limiting factor. So when someone runs dual carbs, that could be doubled to 125hp of possible airbox flow on oem covers. An engine dyno would be useful for these questions.So if I read that right, you've got something that flows nearly as good as a pod filter, but provides OEM protection from water. Oh, and there's an option to be "short" in cases where hood clearance is a problem - numbers pending. Amiright?

Quinc

Buy a Superjet

- Location

- California

Need to find one of those old Westcoast flame arrestors to try! Also be cool to see the HSI and the SE flame arrestor results. =)

WFO Speedracer

A lifetime ban is like a lifetime warranty !

- Location

- Alabama

The old Westcoast water funnel, yes that would be interesting.Need to find one of those old Westcoast flame arrestors to try! Also be cool to see the HSI and the SE flame arrestor results. =)

- Location

- Miami, FL

I have Full Spectrum 49's... do you offer an airbox for these?

- Location

- Buffalo, NY

I believe I have one of these for a 44mm Mikuni. I'll see if I can locate it this week.The old Westcoast water funnel, yes that would be interesting.

- Location

- Spring Lake, MI

Yes, my current version of the hoseclamp bases will work with full spec 48's and 49's. I'll send you a pm to discuss further.I have Full Spectrum 49's... do you offer an airbox for these?

way2manyhobbies2keep

https://www.ebay.com/usr/way2manyhobbies2keep?_trk

- Location

- Sandy Eggo

would live to see some bolt on ones for dual 38's

Stock f/A's arent well loved and need reed spacers or trimming to fit with a girdle head

Stock f/A's arent well loved and need reed spacers or trimming to fit with a girdle head

- Location

- Spring Lake, MI

I've made a prototype design for 38's that seem to work fine. Clearing the head is a big issue for how tight the carbs are pulled against the cylinder. It also requires a special cover to have clearance around the sparkplug boot. That cover worked out well on some kawasaki setups that had that clearance issue as well. Only having three bolts holding it in could be a longevity issue.