Well, I figured I'd start this build thread now to get some help and comments from the experts who have done most of this stuff before. Maybe this thread will help somebody else sometime.

Stuff I'm doing in no particular order:

1.750 engine with 650 electrics

2. shortened hull

3. nozzle/steering throw mod

4. Push-rod Up trim

5. Waterbox mod

6. bilge pump install

7. dual cooling

8. ?

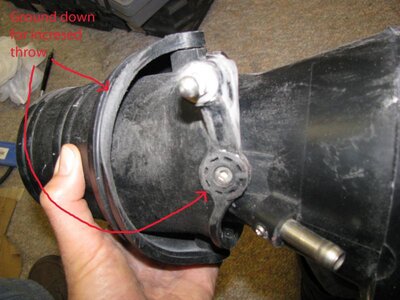

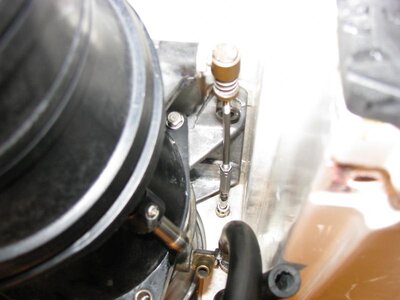

3. First, here's a couple pics of the steering actuator and nozzle. The nozzle was ground down to increase throw side to side and upwards. I heated and straightened the steering actuator arm to get the max throw where the nozzle would just touch the shortened hull each way with full up trim. There wasn't much straightening required with my location of the squirrel cage balls. I also needed to weld the ball for the nozzle onto a bolt at an angle no that the brass coupler wouldn't bind while steering at max up trim. The pics of the nozzle are still with the stock ball. Also, the trim nozzle section is flipped 180° for the push-rod trim mod.

Stuff I'm doing in no particular order:

1.750 engine with 650 electrics

2. shortened hull

3. nozzle/steering throw mod

4. Push-rod Up trim

5. Waterbox mod

6. bilge pump install

7. dual cooling

8. ?

3. First, here's a couple pics of the steering actuator and nozzle. The nozzle was ground down to increase throw side to side and upwards. I heated and straightened the steering actuator arm to get the max throw where the nozzle would just touch the shortened hull each way with full up trim. There wasn't much straightening required with my location of the squirrel cage balls. I also needed to weld the ball for the nozzle onto a bolt at an angle no that the brass coupler wouldn't bind while steering at max up trim. The pics of the nozzle are still with the stock ball. Also, the trim nozzle section is flipped 180° for the push-rod trim mod.