- Location

- Spring Lake, MI

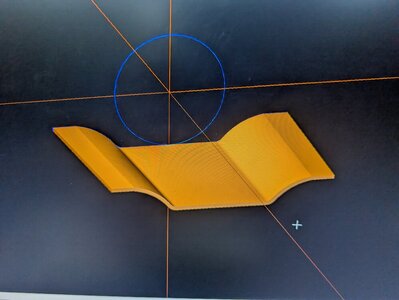

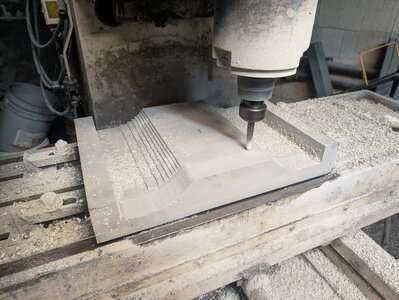

I've done my fair share of fiberglass repair and ufo mounts but this was my first time building a mold and producing a part. Piranha "freak" that never came with a ride plate. Goofy 15" wide with m6 inserts. Went extra long to counteract the shortness of the hull and for future mods. Used cad(cardboard aided design) for initial mockup and later a simple model and 3d print to verify the measurements. I don't own a vacuum pump, gelcoat or other general composite tools so I decided to go with a male/female mold and give it a squeeze. I kept the sides of the male mold tall to act as a guide so the composite thickness would be uniform. The mold itself is "renboard" tooling plastic that has been urethane sealed and brushed with a wax release. Used a combo of biaxial, heavy cloth, and mat in the center to build up an 11 layer plate that ended up at 0.265" at the ends and 0.300 at the center. The mold was designed for 1/4" so close enough. Very little deflection when standing in the middle so it should shear the mounting bolts before breaking. Overall a success and with a quick turnaround of 4 days beginning to end.

Attachments

-

PXL_20260101_184514863.jpg78.8 KB · Views: 38

PXL_20260101_184514863.jpg78.8 KB · Views: 38 -

PXL_20260101_203641887.jpg149.9 KB · Views: 34

PXL_20260101_203641887.jpg149.9 KB · Views: 34 -

PXL_20260101_222406203.jpg176.2 KB · Views: 33

PXL_20260101_222406203.jpg176.2 KB · Views: 33 -

PXL_20260102_180041740.jpg138.4 KB · Views: 34

PXL_20260102_180041740.jpg138.4 KB · Views: 34 -

PXL_20260102_232439252.jpg159.1 KB · Views: 36

PXL_20260102_232439252.jpg159.1 KB · Views: 36 -

PXL_20260104_165028850.jpg152.8 KB · Views: 35

PXL_20260104_165028850.jpg152.8 KB · Views: 35 -

PXL_20260104_204550297.jpg119.7 KB · Views: 30

PXL_20260104_204550297.jpg119.7 KB · Views: 30 -

PXL_20260104_214037033.jpg107.2 KB · Views: 34

PXL_20260104_214037033.jpg107.2 KB · Views: 34 -

PXL_20260104_214040635.jpg122.3 KB · Views: 38

PXL_20260104_214040635.jpg122.3 KB · Views: 38 -

PXL_20260104_214112993.jpg130.6 KB · Views: 38

PXL_20260104_214112993.jpg130.6 KB · Views: 38