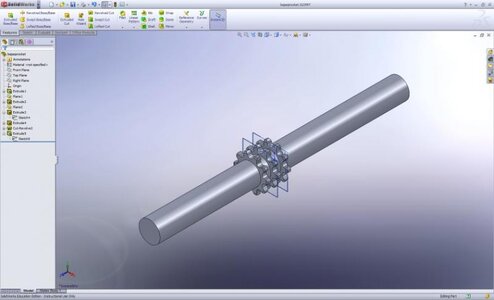

I know theres quite a few people on here who are machinists/engineers. I have been trying for a while to create a toolpath for a part I am making. I was hoping maybe someone could either create the file or set me on the right path.Basically its a solid shaft machined down so that 3 sprockets are protruding from it. It needs to be a solid piece. The piece drawn is what needs to be made. I am using an HAAS SL-20 with live tooling. I have almost all imaginable CAD/CAM software. Preferablly if anyone wants to help me out Esprit is best.

I have a solidworks file of it but I cant attach it. Ill send it to whomever wants to try.

I have a solidworks file of it but I cant attach it. Ill send it to whomever wants to try.