- Location

- Idaho

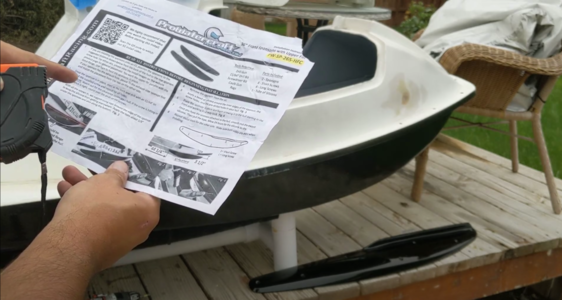

Tubbies went on next.

I'd reccomend Prowatercrafts, Blowsion Destroyers, or Toms Tubbies.

Just follow the instructs, dont be a dummy.

Measure it out - this is specicially important because if you dont, the rear screw may protrude into your foot tray area which would be horrible.

If you are going to make a mistake, error at the side of being too far forward rather than too far backwards.

Put the rear up as high as possible too, and the bottom should be slightly less than flush with the bottom of the hull --- following the hull line all the way forward.

I'd reccomend Prowatercrafts, Blowsion Destroyers, or Toms Tubbies.

Just follow the instructs, dont be a dummy.

Measure it out - this is specicially important because if you dont, the rear screw may protrude into your foot tray area which would be horrible.

If you are going to make a mistake, error at the side of being too far forward rather than too far backwards.

Put the rear up as high as possible too, and the bottom should be slightly less than flush with the bottom of the hull --- following the hull line all the way forward.