- Location

- Reno,NV

Quick build instructions for everyone who has inquired in the past... and for everyone like me who is missing doing "Ole scoo tricks" having that dam BOB..;0)

Again these are just my recommendations after building numerous Squares and utilizing ideas from other members here i have found these specific techniques to best and ensure long subs and hood rides as well as ongoing fountains without stalling/flooding the engine bay.

"opinions will differ "

The build will be kept down to bare info and I will cut some corners which some of the new peeps on the board might want to follow up with additional questions, furthermore this is a budget build.

- SCUPPER

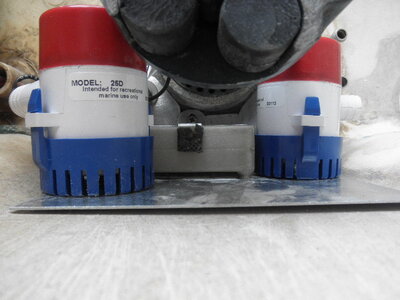

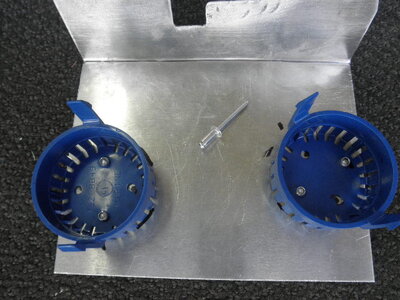

- DUAL RULE 500 BILGE & PLACEMENT OF BILGE OUTLET

- DUAL COOLING

- CUSTOM ALUMINUM PLATE FOR BILGE & OEM BILGE

- HOOD MOD & HANDHOLDS

- HOOD STRAP & HOOD SEAL

Again these are just my recommendations after building numerous Squares and utilizing ideas from other members here i have found these specific techniques to best and ensure long subs and hood rides as well as ongoing fountains without stalling/flooding the engine bay.

"opinions will differ "

The build will be kept down to bare info and I will cut some corners which some of the new peeps on the board might want to follow up with additional questions, furthermore this is a budget build.

- SCUPPER

- DUAL RULE 500 BILGE & PLACEMENT OF BILGE OUTLET

- DUAL COOLING

- CUSTOM ALUMINUM PLATE FOR BILGE & OEM BILGE

- HOOD MOD & HANDHOLDS

- HOOD STRAP & HOOD SEAL

Attachments

-

P4180035.JPG82.1 KB · Views: 143

P4180035.JPG82.1 KB · Views: 143 -

P4180037.JPG84.4 KB · Views: 132

P4180037.JPG84.4 KB · Views: 132 -

P4180038.JPG82.5 KB · Views: 135

P4180038.JPG82.5 KB · Views: 135 -

P4180039.JPG84.6 KB · Views: 134

P4180039.JPG84.6 KB · Views: 134 -

P4180040.JPG85 KB · Views: 139

P4180040.JPG85 KB · Views: 139 -

P4180041.JPG84.2 KB · Views: 135

P4180041.JPG84.2 KB · Views: 135 -

P4180042.JPG85.5 KB · Views: 139

P4180042.JPG85.5 KB · Views: 139 -

P4190043.JPG83.8 KB · Views: 134

P4190043.JPG83.8 KB · Views: 134 -

P4190044.JPG82.9 KB · Views: 137

P4190044.JPG82.9 KB · Views: 137

Last edited: