Being that this 4Runner was an automatic, I also had to deal with the transmission hump in the cab. This hole is designed to accept the automatic transmission and applicable trim for the shifter. Because I had a manual transmission donor vehicle, I opted to carefully cut the entire mounting out of the donor truck and overlay it into the new truck. Because these trucks for the most part were 95% the same, I was able to overlay the trimmed mount and basically "snap" it down onto the existing floor. I could then find the correct template for the metal I needed to remove from the new truck. I drilled the holes for the new mount also and used the same plastic inserts to secure the boot. I smoothed everything out along the edges and made sure I had a tight fit. I decided to silicone the underside of the new piece and insert the plastic inserts, which firmly held the piece in place. Boom, smooth as butter!

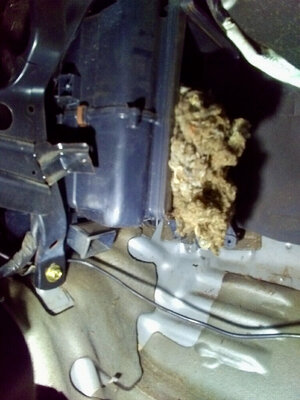

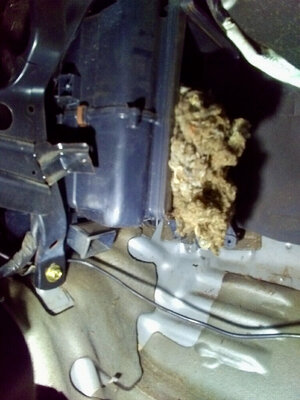

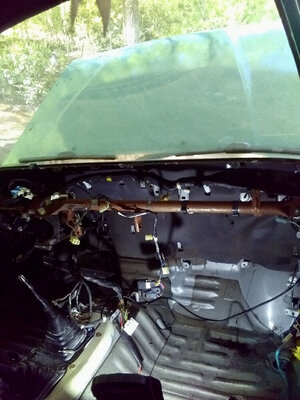

I had to remove the complete ducting system, heater core, fan and all the ducting. I had been losing a battle with a mouse that would not vacate the duct work! Kept eating the peanut butter off of the traps... Well I pulled his house, or I should say MANSION out and cleaned all of the ducting very thoroughly. That was a pain.

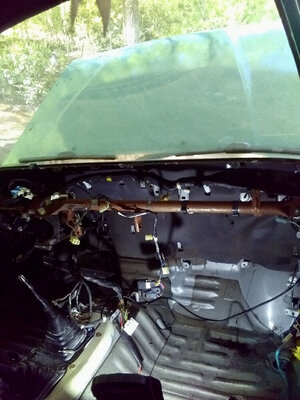

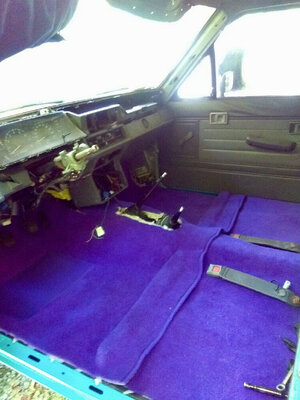

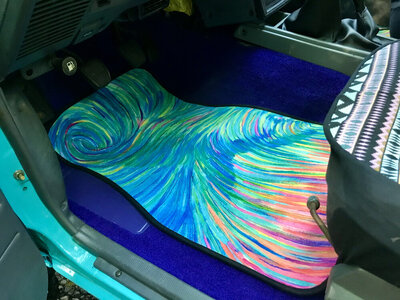

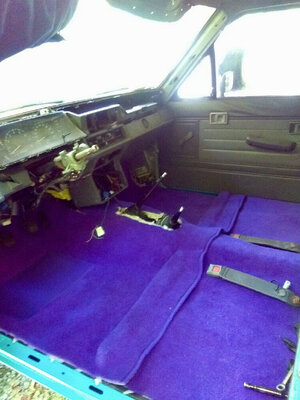

Finally after re-assembling the entire vent system, cleaning the pile off goo off the floorboard from the mouse waste (yuck) and also scrubbing down the entire floor pan 1 last time, I was able to install the front carpet. WOO HOO!

This had proved to be a very difficult process, The carpet is not trimmed to size nor does it have any holes for seatbelts and console mounting. So, fitment was very nice after a couple hours of slowly and carefully trimming the pieces to fit. I was also able to install some of the dash not that the "mouse house" was removed.

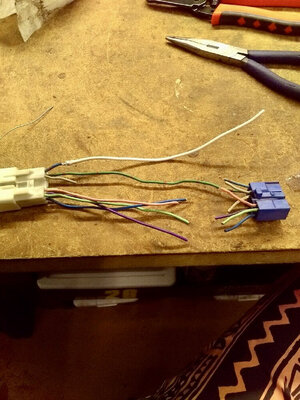

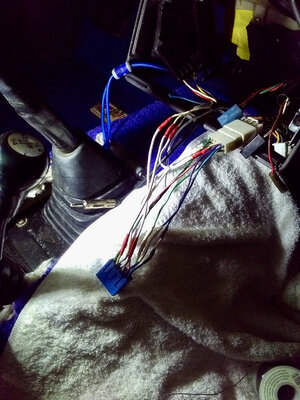

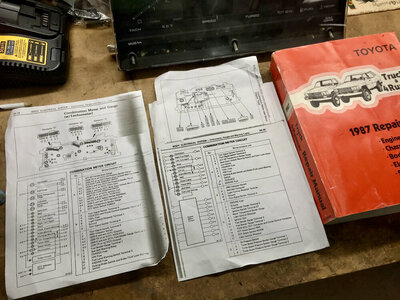

Onto greener pastures, I started to take closer look at the radio wiring and wiring in general. I found all of the proper locations for relays and fuse panel mounting/buzzer etc. I did all of the wiring for the amplifier/subwoofers and routed everything neatly underneath the carpet/panels/console. The real challenge was fixing the trashed radio wiring harness! Luckily I enjoy soldering and pinning connectors so I was excited to fix this disastrous mess. I have a few OEM Toyota service manuals that were very helpful for getting everything sorted and connected properly. I started with this garbage...