You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blueprinted Pump

- Thread starter WaterX117

- Start date

2lick

Brap!!!

- Location

- Limerick, PA

rough water hook up....

check over on pwctoday.com there is a how to nicely done....

all you need is time and a dremel

check over on pwctoday.com there is a how to nicely done....

all you need is time and a dremel

- Location

- So. IL

romack991

homebrewed

- Location

- Warsaw, IN

Mark44

Katie's Boss

- Location

- 100% one place

I don't think so. IMO

Mark44

Mark44

2lick

Brap!!!

- Location

- Limerick, PA

if you have the time... its gonna help.....

i wouldn't put down time during ridding season to do it thought... its more something to do over the winter when your bored....

i wouldn't put down time during ridding season to do it thought... its more something to do over the winter when your bored....

Is it worth it?

I don't know. But my time is cheap, my dremel works well, so I do stuff like that occasionally. It certainly can't hurt.

aqua

the taco

- Location

- Jefferson City, MO

i did mine a couple of weeks ago......question is this. should it be a nice smooth surface like polished or should it be rough like 60 grit paper would make it. would smooth be so bad....after all polished exhaust ports are good. i have heard both sides....some say smooth, some say rough. i have heard that a hull is more efficient at lower speeds if it is rough but would that apply to the high speed flow through the stator. from what i have heard....faster speed water flow is less affected by the surface that it is flowing over. what is everyone elses take on this?

2lick

Brap!!!

- Location

- Limerick, PA

yeah....

i think both have there pros....

solas props... polished

skat trak props.... rough

i think both have there pros....

solas props... polished

skat trak props.... rough

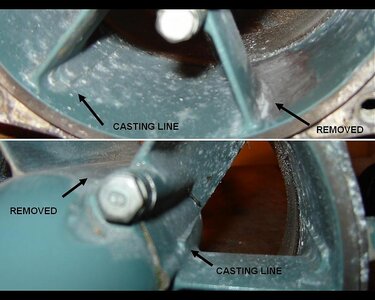

shouldnt make a huge difference I dont think. The idea is the smoothest flow of water possible with the least turbulence, 60 grit finish is so much less an obstacle then the giant, sharp, casting marks that are 90 degree angles and such, also causing each vein to vary in size. I wouldnt worry about smoothing it or roughing it, just dremel the castings and leave it. The turbulence cause by the valleys created by 60 grit paper would be negligible. The only reason I could see for that is to make lateral sandings the way the water flows to help 'tracking' but thats unnecessary.

- Location

- So. IL

I don't think so. IMO

Mark44

I agree with mark I didn't change a thing on my ski the wonter I blueprinted my pump and I couldn't tell a bit of difference. I agree thatmy own labor is cheap..... Hell my labor is cheap anywhere you should see my pay check. But anyhow if you have to do something bore your exhaust manifold out a mm or 2 and polish that up.

FL-cracker

X-H2O

- Location

- old exit 72 Melbourne

Thats some time you spent there! Nice job.

aqua

the taco

- Location

- Jefferson City, MO

i thought about sharpening the trailing edges of my stators also but when i put the reduction nozzle on i could see where the stators meet up with the ones in the reduction nozzle so i didnt. but what i did do was sharpen the trailing edges on my intake grate and filled in that hollowed out area at the rear of the grate with jb weld. :smile:

Ideally, most of the stuff should be shaped like long tear drops (the fabled ones everyone thinks of, not the realistic hamburger patty ones), with the 'fat and round' edge of the tear facing where water comes in, and the

sharp' edge of the tear facing the water's exit. However, the difference in the veins that would make would be minute and infintesimal IMO.

sharp' edge of the tear facing the water's exit. However, the difference in the veins that would make would be minute and infintesimal IMO.

G

Goose

Guest

just doin some thinking out loud but anyone ever think of taking some kind of epoxy and spreading it in between the vaines around were the driveshaft bearing is then smooth it out wouldnt that kinda make the same effect as the tbm pump cone if you understand where imtalking about and would it hold?