Hfurll

Henry

- Location

- Breckenridge Colorado

Started this about a week ago.....

I have everything i need with exception of a 750 Limited factory pipe ( FOUND ONE))

The plan is to

HULL

I have everything i need with exception of a 750 Limited factory pipe ( FOUND ONE))

The plan is to

HULL

- Flat Deck a Js hull, getting rid of the silly small tray

- Cut out the bottom of a 650SX and Marry it to the Js Hull

- Alter Bulkhead for sx style bearing

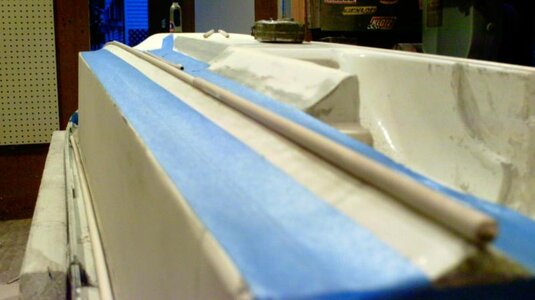

- Enlarge the strakes to a more modern design

- Fix existing holes in hull

- Alter engine compartment to accept a 750 Limited pipe

- Install a set of Tubbies ( surfjetlouie's) rip

- 92 750 SX ---stock bore

- port and intake work

- 650 Jetnetics Aluminum Flywheel with 650 reg in 550 E-Box

- WestcoastHead 28 domes

- Dual SBn 44's

- FACTORY PIE ( LOOKING)

- Mariner 550 waterbox altered with larger in and outlets

- Fueltank----not there yet

- 550sx Driveshaft

- 650 blueprinted pump

- TBM stuffer

- Prop debateable----12-17 Large hub or a tad taller?

- C.A.T.S--- X2 noz

Attachments

-

build 2.jpg43.5 KB · Views: 79

build 2.jpg43.5 KB · Views: 79 -

build 1 .jpg70.9 KB · Views: 121

build 1 .jpg70.9 KB · Views: 121 -

bondoed strakes.jpg36.6 KB · Views: 92

bondoed strakes.jpg36.6 KB · Views: 92 -

strakes.jpg32.1 KB · Views: 63

strakes.jpg32.1 KB · Views: 63 -

first coat on dowels.jpg39.3 KB · Views: 67

first coat on dowels.jpg39.3 KB · Views: 67 -

dowled 2.jpg37.7 KB · Views: 78

dowled 2.jpg37.7 KB · Views: 78 -

fitment.jpg31.4 KB · Views: 54

fitment.jpg31.4 KB · Views: 54 -

build 4.jpg52.1 KB · Views: 81

build 4.jpg52.1 KB · Views: 81 -

build 3.jpg37.7 KB · Views: 83

build 3.jpg37.7 KB · Views: 83 -

glassed in.jpg46.2 KB · Views: 58

glassed in.jpg46.2 KB · Views: 58

Last edited: