Went on a trip again to visit my good buddy in Alabama!... This time just a double, no car trailer thankfully.

We needed a replacement motor for a friends 550, and a friend (who got cold feet) wanted the sxi pro

So stared at the weather all weekend like a hawk, we got 3 inches of snow here in ATL, and immediately it turned to a slushy mess.

Managed to have some fun though with friends before it all rinsed away.

Seller was in stock at his lake residence where he stores his fun stuff, so wanted to get the job done. Saw a good slot on Saturday where we could get back before temps got too low and everything froze back over.

Made the Journey!

I wasn't going to back out of the SXI PRO after agreeing to purchase it, decided I'll make something of it we know I love a good project. Got all sorts of various parts & engines.... But alas I had a double.. with one empty slot.. So we know what happened.

Obligatory Buc-ee's Picture

Finally All home, ZERO road drama, nobody was out, roads were gross but zero holdups.

NEXT DAY:

Let's start with a quick detour...

1988 650SX.. It's going to a buddy but we can talk about my short ownership.

I knew it was a good unit, didn't bother trying to run it or anything there, probably hasn't ran in years.

Some liquid encouragement she fired right up!

Back to the pro... Got it all cleaned up and out in the sun.

Plan is typical whole refresh.

Some pain points I'm not overly stoked about.

Fiberglass repairs:

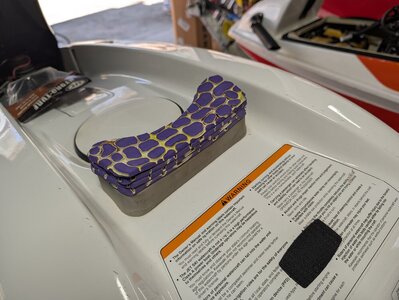

something is DEFINITELY hiding under this sticker

Missing parts:

I have the i-body carbs... yes I know "jUsT rUn tHe foRTY sIx"

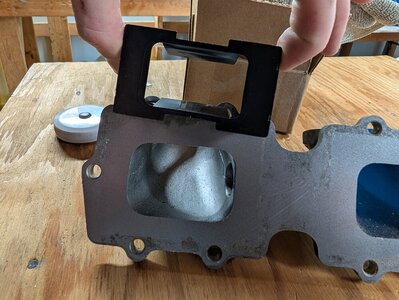

I am in need of the manifold and airbox arrangement. missing those pieces... DM me if you have!

Either way should be a fun little project when I have the time!

We needed a replacement motor for a friends 550, and a friend (who got cold feet) wanted the sxi pro

So stared at the weather all weekend like a hawk, we got 3 inches of snow here in ATL, and immediately it turned to a slushy mess.

Managed to have some fun though with friends before it all rinsed away.

Seller was in stock at his lake residence where he stores his fun stuff, so wanted to get the job done. Saw a good slot on Saturday where we could get back before temps got too low and everything froze back over.

Made the Journey!

I wasn't going to back out of the SXI PRO after agreeing to purchase it, decided I'll make something of it we know I love a good project. Got all sorts of various parts & engines.... But alas I had a double.. with one empty slot.. So we know what happened.

Obligatory Buc-ee's Picture

Finally All home, ZERO road drama, nobody was out, roads were gross but zero holdups.

NEXT DAY:

Let's start with a quick detour...

1988 650SX.. It's going to a buddy but we can talk about my short ownership.

I knew it was a good unit, didn't bother trying to run it or anything there, probably hasn't ran in years.

Some liquid encouragement she fired right up!

Back to the pro... Got it all cleaned up and out in the sun.

Plan is typical whole refresh.

Some pain points I'm not overly stoked about.

Fiberglass repairs:

something is DEFINITELY hiding under this sticker

Missing parts:

I have the i-body carbs... yes I know "jUsT rUn tHe foRTY sIx"

I am in need of the manifold and airbox arrangement. missing those pieces... DM me if you have!

Either way should be a fun little project when I have the time!