Mr Bojangles

Lord of the Dance

- Location

- Brevard County, Fl

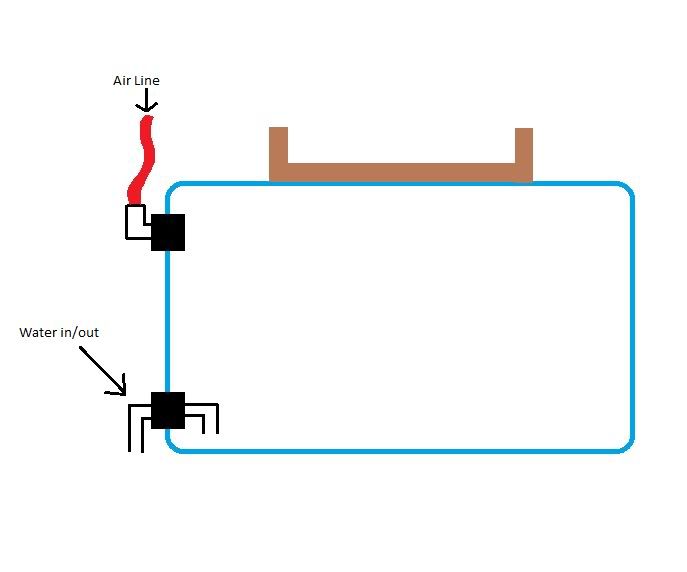

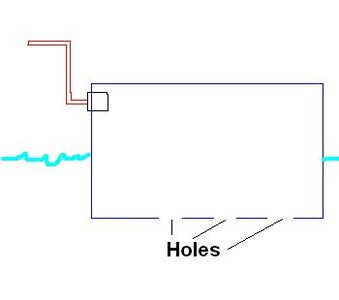

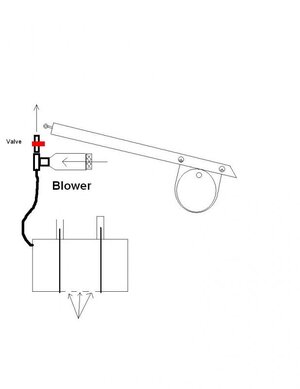

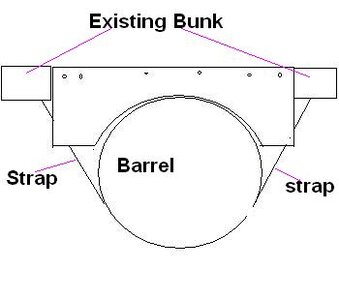

Ok, I'm going to do the air pump. I did some digging and the hydrohoist uses just a blower for the air pump and I have one on my air dock I can tap off of. It looks like I will now move the drum back and on the bottom drill a 1/2 hole and on the side with the 2 inch fitting I will tap it and put a air hose line that will go to a valve that will let me vent the air, and then a fitting to let me put the air hose on and fill it up. I should hopefully make loan and launching easier since it will be lower. So are you sure hydrohoist just puts a small hole in the lowest point? I do see in the vids that when bubbles come out the bottom it's full. It seams like it would work, I just want to make sure before I drill a hole on the bottom of the tank and hope there is no slow air leak from the tank plugs otherwise it will slowly leak and sink when I'm not there