I'll make this real simple for you Mark, no tape measure needed.

Lay the pole I shipped back to you on a bench.

Push a 2-3' straight rod thru the pole bushings (same diameter of the bushings).

Put the short edge of the square on the rod and have the long edge run up the side of the pole.

Check out the detailed blueprints below, that I had professionally drawn to assist you in this challenge.

I don't understand why measuring that old pole is now important again. What was important and the whole reason for my reply was making sure the new pole you were going to be warrantied would be straight.

I said above your old pole was off. I did not deny that, and what was more important than going into detail on that old pole, is again making sure you got a quality replacement.

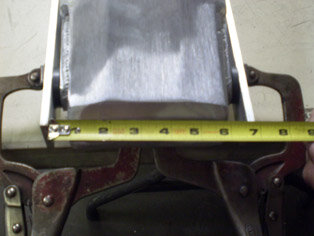

The first measurement we did above on the new pole is the same as this measurement if you are trying to have me perform. The first form of measurement I provided above actually put the sides of the hood being completely flush with the bushing surface and flat all the way up. If you look at the picture from above and at the straight bar you can see where the pole lines up on a straight edge which is the same thing Jeff is trying to explain with a short edge.

I can't measure that old pole to begin with because the pole was disposed of because of its defect, I personally did not want to keep around a blem product anymore.

However, as soon as the pole showed up we did the same 2 measurements above which confirmed the old pole was off to the left. The second measurement of the bushing holes confirmed that the CNC watercut bushing holes were not any further back or fourth from each other I got the same measurement of 37 5/8th from the bolt holes to where the true center line of the steering hole, which would of been 5/8th of an inch over to the right.

No I did not take photos of these measurements because it was for Mike and I to both understand the ultimate problem with the warranty issue and take notes for the new pole production and QC strategy.

I am not playing any smoke and mirrors with our measurements, these are means of measuring from the head manufacturer who is a long time professional machinist and knows what he needs to do in order to get a certain measurement and who will not settle for using a short edge to determine that a handlepole is mechanically straight. There is no need to continue this discussion more about a part that is no longer relevant. It was a manufactured item, it was a blem, we had the customer return it, we then provided the best evidence and assurance that his new warranty pole would be straight, the customer was still not satisfied, so we returned the money to the dealership he purchased it from upon demand. We did our best to assist a customer and that was my main concern.