Quinc

Buy a Superjet

- Location

- California

Built this over the winter with my 8 year old. He took every nut and bolt off the ski and did the fiberglass! So please give him a like and sub on youtube.

Max Speed run:

Ski ready to ride weight is 226lbs. Battery weighs 35 pounds! Once I figure out if I want to stay with sprockets or swap to coupler I will shave some weight off or maybe go to aluminum. Also thinking I can cut out the hood liner for a few lbs.

Specs:

Ski 1986 300sx

Skat 16 impeller

Motor sprocket 14T Driveshaft sprocket 10T (Did this so I could adjust rpm/torque with sprockets)

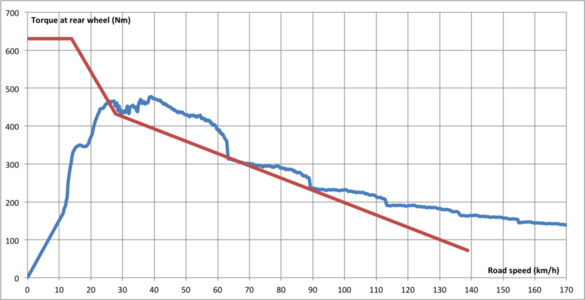

Still trying to Figuring out the rpms Vs Torque for a jetski.. I also have a Skat 15 and PJS 17 impeller to try. In the video I think the top speed was around 15mph.

Cool thing about it is you can adjust 3 separate speed settings so when my 4 year old rides it I can keep the speed around 10mph for him.

If it turns out to be awesome I will probably try the 8000w motor next.

Max Speed run:

Ski ready to ride weight is 226lbs. Battery weighs 35 pounds! Once I figure out if I want to stay with sprockets or swap to coupler I will shave some weight off or maybe go to aluminum. Also thinking I can cut out the hood liner for a few lbs.

Specs:

- QS-120 motor 2000w / Maximum Torque: 20N.m to 49.6N.m. (more info on motor and controller specs)

- Votol em-100 controller

- 72v lithium battery capable of 800amp peak power.

- ANT 300a bms

Ski 1986 300sx

Skat 16 impeller

Motor sprocket 14T Driveshaft sprocket 10T (Did this so I could adjust rpm/torque with sprockets)

Still trying to Figuring out the rpms Vs Torque for a jetski.. I also have a Skat 15 and PJS 17 impeller to try. In the video I think the top speed was around 15mph.

Cool thing about it is you can adjust 3 separate speed settings so when my 4 year old rides it I can keep the speed around 10mph for him.

If it turns out to be awesome I will probably try the 8000w motor next.

Last edited: