- Location

- Western NY

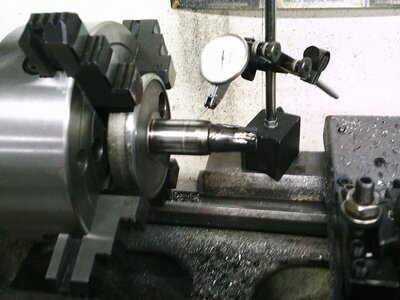

I was going to re-pin my stock crank to a 4-6mm stroker. I had seen somewhere that some of the earlier stroker cranks up to 6mm were re-pinned stock cranks. Anyone done this, anyone still doing this? I pressed apart a blown stock crank last night. Looks like you could probably get away with 5mm adding a sleeve to completely remove the old crank pin hole, or barely 8mm with no sleeve and weld the pin after assembly. This is with 26mm pins for small pin kawi rods.

I am curious if anyone has seen one of these stroked stock cranks, did they press a sleeve in or leave some of the old pin hole, weld up some material before cutting new pin hole, or maybe make a little eyelet to press in between old pin hole and new pin?

On a side note does anyone know if someone still makes long rod 5mm stroker cranks? It sounded like the hpe setups worked pretty well before he stopped making them. I could possibly machine crank webs for people out to 5mm strokers for 133 rods but I have little interest in assembling cranks lol.

I am curious if anyone has seen one of these stroked stock cranks, did they press a sleeve in or leave some of the old pin hole, weld up some material before cutting new pin hole, or maybe make a little eyelet to press in between old pin hole and new pin?

On a side note does anyone know if someone still makes long rod 5mm stroker cranks? It sounded like the hpe setups worked pretty well before he stopped making them. I could possibly machine crank webs for people out to 5mm strokers for 133 rods but I have little interest in assembling cranks lol.