This would be a good time to cut out the whole tray, defoam and add foot holds.

Situations vary, so here's some if, then, else to work from.

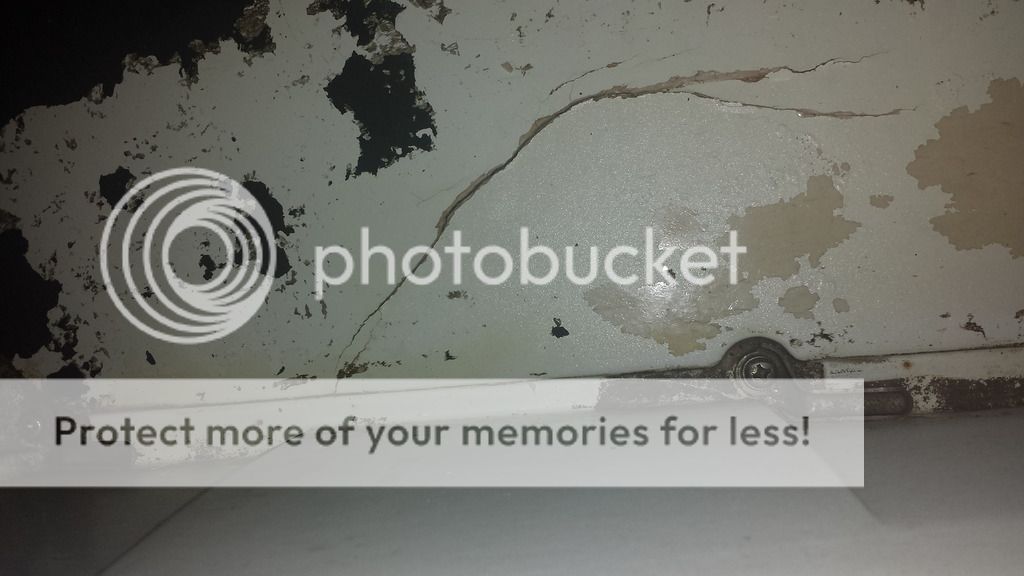

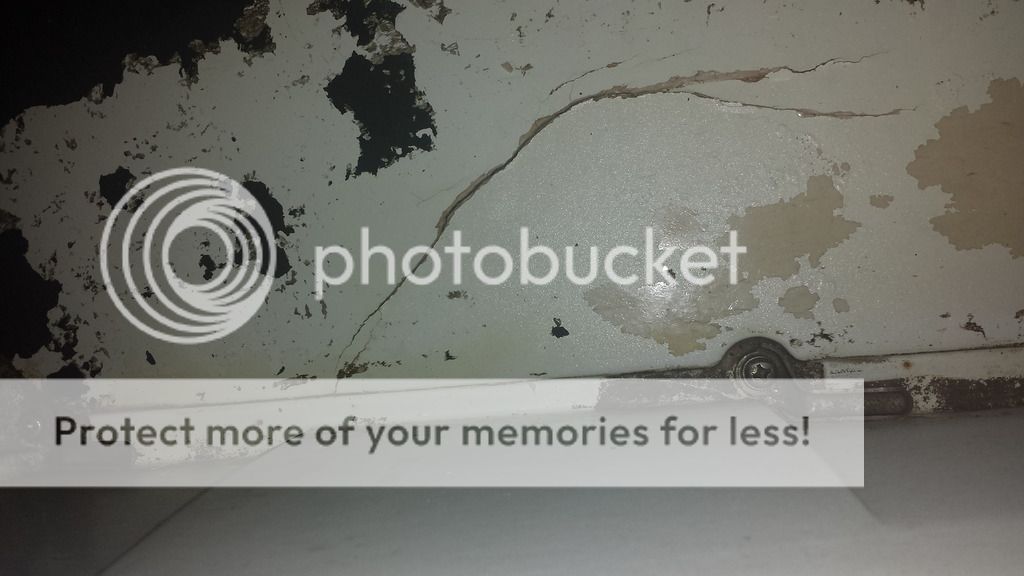

If you want to do a minimal amount of work, drill holes at the ends of the cracks to stop the cracking. Be careful to not cut into the pump tunnel.

If it is only a fairly superficial crack, you can glass over it.

If it is a very deep crack then it would be a good idea to grind out all of the damaged material.

If you cut the crack out and it's super thin, pack it with epoxy mixed with microspheres. If it's less than about 1/4" pack it with epoxy mixed with milled fiber. If it's a substantially wide or larger area, you need to use actual glass.

Layup glass to cover the crack. It's high impact, so I would cover a substantial area. I would use biax. 1 layer of 1208 may be sufficient for a small cut area but you should probably do 2, maybe even 3 if you are abusive. Finish with a layer of conform cloth to get a nice finish. Vacuum bagging it can save weight, in which case I would definitely do 3 layers. You can bag it cheap with storage bags and a shop vac.

Do not sand into the fiber. Cover with epoxy mixed with microspheres and sand smooth.

I would run at least 9mm hydro turf underpad. It would both be comfy and reduce stress on the repair.