I just bought my second Epic cdi, but this time I purchased the software as well. I had Art (Jetworks) program my last one and it worked flawlessly. I'm looking to get input from those who have found curves that work well with their setup.

Please post the following:

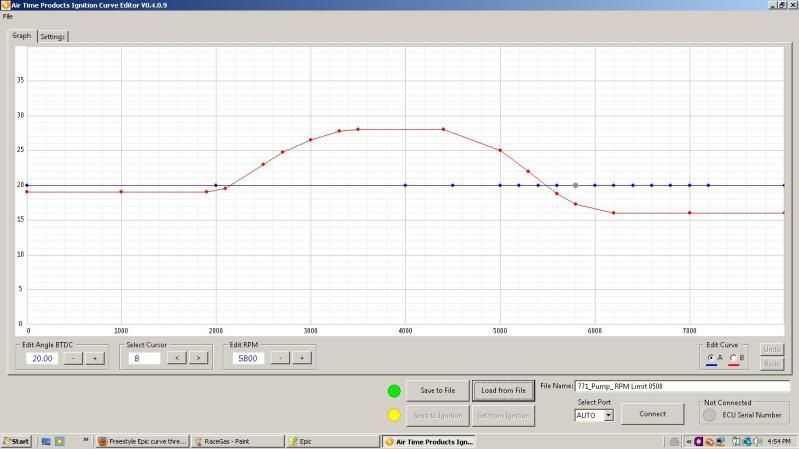

1. Epic curve and/or numerical curve settings

2. Engine/pump/ski specs

3. Flatwater or Surf riding

Please post the following:

1. Epic curve and/or numerical curve settings

2. Engine/pump/ski specs

3. Flatwater or Surf riding