Aquaholic

World's Oldest Teenager

- Location

- San Diego, CA.

Yo Peeps:

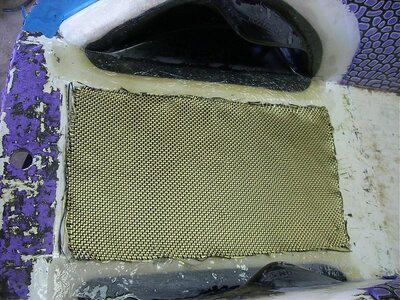

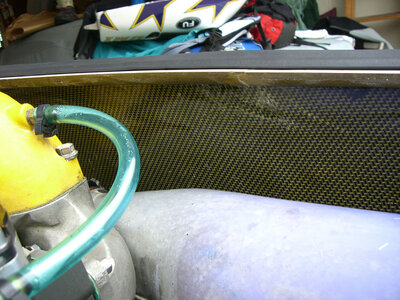

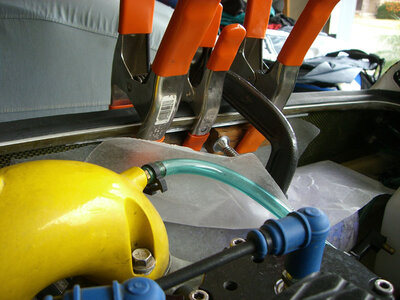

I've been adding layers of carbon/kevlar to the sides of my hull in an attempt to strengthen this old dog. I had some pretty substantial cracks develop in the usual areas, last season. Primarily on the top deck, middle of the boat, near the hood seal, resulting from numerous flopped, side landings.

I thought that I had things sorted out, only to be totally bummed after seeing new cracks appear so early in the season.

My idea is this...have any of you incorporated strips of aluminum with glass over that, to act as strengthening ribs for your hull?

I'll try to take some pics of the cracks...but I'm not sure that you'll be able to see them.

I've incuded some shots of some other reinforcing that I've done to the boat.

Thanks in advance.

Aqua

I've been adding layers of carbon/kevlar to the sides of my hull in an attempt to strengthen this old dog. I had some pretty substantial cracks develop in the usual areas, last season. Primarily on the top deck, middle of the boat, near the hood seal, resulting from numerous flopped, side landings.

I thought that I had things sorted out, only to be totally bummed after seeing new cracks appear so early in the season.

My idea is this...have any of you incorporated strips of aluminum with glass over that, to act as strengthening ribs for your hull?

I'll try to take some pics of the cracks...but I'm not sure that you'll be able to see them.

I've incuded some shots of some other reinforcing that I've done to the boat.

Thanks in advance.

Aqua

Attachments

Last edited: