waxhead

wannabe backflipper

- Location

- gold coast

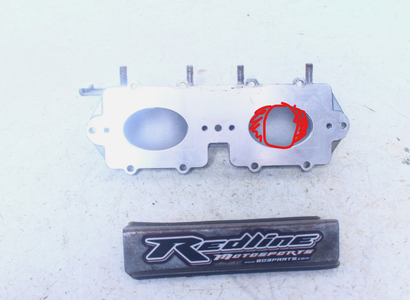

A lot of riders assume all intake manifolds are basically the same — a simple piece that connects the carburetors to the reed cage.

That old way of thinking has stuck around since the 90s, and so has the habit of “blending the manifold into the reeds” to make it look smooth.

The reality is this:

modern two-stroke tuning is about wave control, not polishing.

And that’s exactly why our intake manifold was designed the way it is.

We designed the Wax Racing manifold with one core goal:

keep the same top-end flow.**

The throat size is identical to the best high-RPM manifolds, so peak power isn’t restricted.

The difference is in the shaping — it’s built to manage the pressure wave properly, not just provide a straight passage.

This is why you feel:

All while keeping the exact same top-end RPM you’d expect.

Two-stroke engines don’t run on “steady airflow.”

They run on rapidly changing pressure waves.

A manifold that’s just a blended tunnel works fine for forward airflow…

but it also makes it easy for reverse pulses to travel backward up the intake.

That’s how you lose:

The Wax Racing manifold is shaped to do the opposite:

It acts like a proper waveguide, not just plumbing.

The old ideas of “blend everything” and “open it up so it flows more” ignore how two-stroke intake waves actually behave.

Using modern understanding of:

…we shaped the manifold to work with the engine, not against it.

There’s real testing and real thought behind this design — not just smoothing everything shiny and hoping it works.

You’ll notice:

That old way of thinking has stuck around since the 90s, and so has the habit of “blending the manifold into the reeds” to make it look smooth.

The reality is this:

modern two-stroke tuning is about wave control, not polishing.

And that’s exactly why our intake manifold was designed the way it is.

Built for Torque First — Without Choking the Top End

We designed the Wax Racing manifold with one core goal:

**Hit harder down low,

keep the same top-end flow.**

The throat size is identical to the best high-RPM manifolds, so peak power isn’t restricted.

The difference is in the shaping — it’s built to manage the pressure wave properly, not just provide a straight passage.

This is why you feel:

- snappier throttle

- stronger holeshot

- better pull before the pipe

- cleaner transition into mid-range

All while keeping the exact same top-end RPM you’d expect.

Not Just a Connector — A Functional Part of the Power System

Two-stroke engines don’t run on “steady airflow.”

They run on rapidly changing pressure waves.

A manifold that’s just a blended tunnel works fine for forward airflow…

but it also makes it easy for reverse pulses to travel backward up the intake.

That’s how you lose:

- consistent jetting

- bottom-end torque

- clean throttle response

The Wax Racing manifold is shaped to do the opposite:

- direct forward pulses cleanly into the reeds

- resist reverse pulses trying to travel out of them

- keep a high-speed air column packed at the reed face

- stabilise the carb signal

It acts like a proper waveguide, not just plumbing.

Modern Tuning Knowledge — Not Outdated Blending

The old ideas of “blend everything” and “open it up so it flows more” ignore how two-stroke intake waves actually behave.

Using modern understanding of:

- pressure-wave direction

- reversion flow

- reed timing

- signal stability at the carb

- air-column behaviour during reed closure

…we shaped the manifold to work with the engine, not against it.

There’s real testing and real thought behind this design — not just smoothing everything shiny and hoping it works.

What You’ll Feel on the Water

You’ll notice:

- harder hit off the bottom

- better drive through corners

- cleaner throttle when loading the pump

- stronger early acceleration

- no drop in top-end pull

Your jetting becomes more predictable too, because the intake pulses feeding the carb are more stable.