customride0105

Site Supporter

- Location

- sterling va

i bought a set of cases off of here and its been several mths ago just now getting around to putting the motor together.

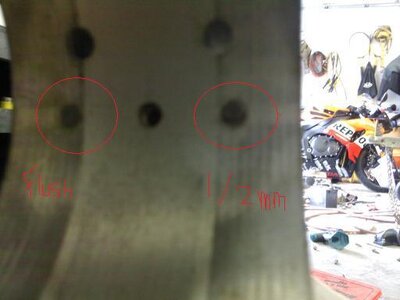

went to just sit the crank in there and noticed 2 of the dowel pins a smached down into the top half of the case. its the middle 2 the smaller ones.

my question is how do i get them out... or is it ok if i just put the crank in and make sure the holes are lined up..

went to just sit the crank in there and noticed 2 of the dowel pins a smached down into the top half of the case. its the middle 2 the smaller ones.

my question is how do i get them out... or is it ok if i just put the crank in and make sure the holes are lined up..