Mike W

Infidel

- Location

- North Florida

I guess I need a deeper hole saw. I have a Worx 201 I kept from my '98 I parted out.If your reffering to the one behind the firewall, my holesaw cut clean through it as I didn't know it was there. What are you going to use for an intake grate for the pump?

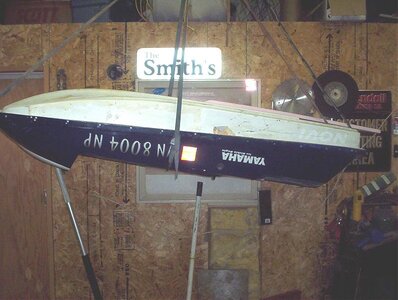

A guy over on PWCtoday from the Tampa area.nice mike!

where'd you find it???

It was a good find.

Last edited: