- Location

- Connecticut

Hi all, I think I found a great way to adapt an aftermarket turn plate to the stock Superjet steering system.

What you need:

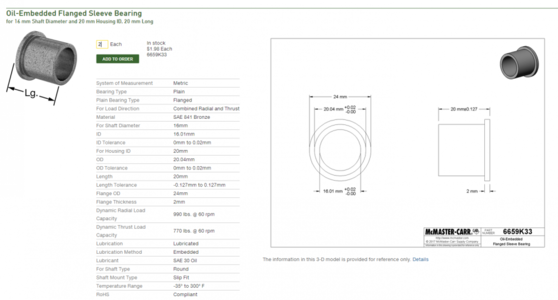

- (2) Bronze Flange Sleeve Bearings (16mm ID, 20mm OD, 20mm L), $3.00 at your local hardware store

- M16 x 55mm Hex Head Screw, $1.30 at your local hardware store

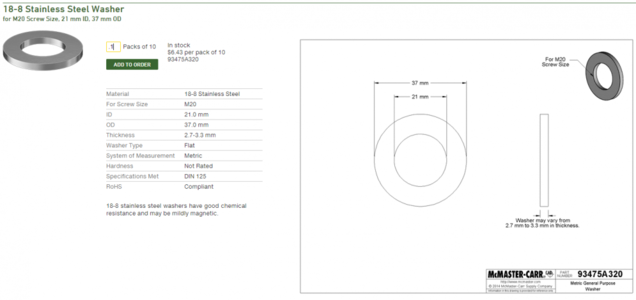

- M20 Washer, $0.90 at your local hardware store

- Double Split Shaft Collar (for 16mm shaft), $15.00 at your local hardware store

- Stock Nylon Bushings from your Superjet

I should have an image of everything you need to buy. You may want to make sure everything is Stainless Steel. If you can only find a Black Oxide Shaft Collar, simply replace the screws that come in it with SS Screws, and keep it greased.

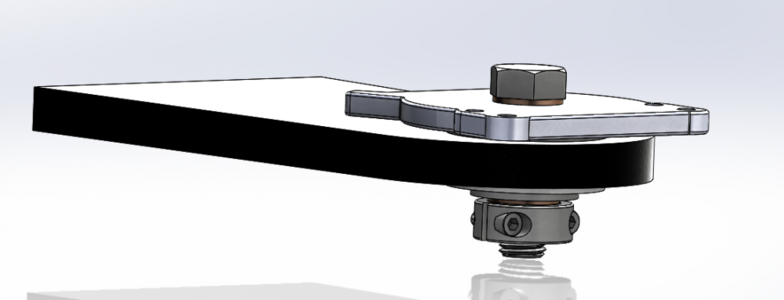

See the attached exploded view for how it goes together (The silver plate is the turnplate, and the black plate is your pole). The shaft collar is what holds it all in. If you want to really tighten your steering, buy any M16 Nut, tighten it against the bottom of the shaft collar, then tighten your shaft collar, and remove the nut. Grease EVERYTHING. These components should all fit very tightly together. I haven't ridden on this setup yet, but it feels VERY smooth! I hung off my bars and banged down on the ends like an angry gorilla and it seems to stay tight. I will update after I ride (maybe a week or 2 in CT).

What you need:

- (2) Bronze Flange Sleeve Bearings (16mm ID, 20mm OD, 20mm L), $3.00 at your local hardware store

- M16 x 55mm Hex Head Screw, $1.30 at your local hardware store

- M20 Washer, $0.90 at your local hardware store

- Double Split Shaft Collar (for 16mm shaft), $15.00 at your local hardware store

- Stock Nylon Bushings from your Superjet

I should have an image of everything you need to buy. You may want to make sure everything is Stainless Steel. If you can only find a Black Oxide Shaft Collar, simply replace the screws that come in it with SS Screws, and keep it greased.

See the attached exploded view for how it goes together (The silver plate is the turnplate, and the black plate is your pole). The shaft collar is what holds it all in. If you want to really tighten your steering, buy any M16 Nut, tighten it against the bottom of the shaft collar, then tighten your shaft collar, and remove the nut. Grease EVERYTHING. These components should all fit very tightly together. I haven't ridden on this setup yet, but it feels VERY smooth! I hung off my bars and banged down on the ends like an angry gorilla and it seems to stay tight. I will update after I ride (maybe a week or 2 in CT).