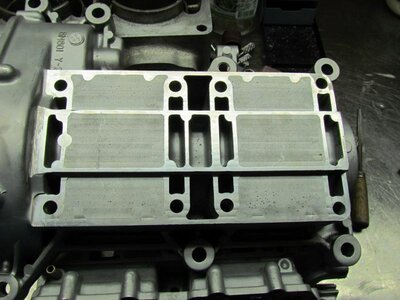

I'm curious, how do you do it? I heard JB was the best stuff to use. I got the Industroweld, the 10oz kit.

JB weld says you can thin it with acetone to pour. Would you guys advise against this?

I also head you can heat the JB weld but I just can't find the process when searching.

I see alot of case porting threads but not much on filling the cases with epoxy. Lets hear, how do you do it?

Thanks!

brandon

JB weld says you can thin it with acetone to pour. Would you guys advise against this?

I also head you can heat the JB weld but I just can't find the process when searching.

I see alot of case porting threads but not much on filling the cases with epoxy. Lets hear, how do you do it?

Thanks!

brandon